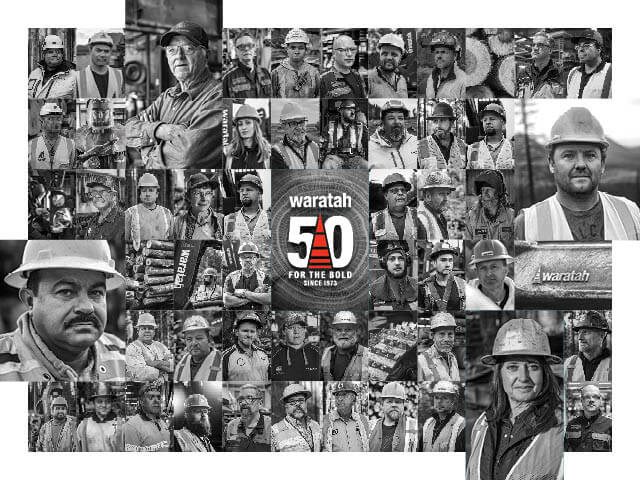

Waratah Forestry thanks its loyal customers

Waratah Forestry Equipment is celebrating 50 years of innovation within the forestry industry and thanking its customers for decades of trust and loyalty to the brand.

“We’re proud to celebrate our 50th anniversary this year thanks to our loyal customers and dedicated team members across the globe,” said Heather Robinson, general manager of worldwide distribution at Waratah. “It’s exciting, because we are in a unique position to offer our customers experience, expertise and innovation.”

Waratah customers are a testament to the company’s reliability and legacy. While the industry has changed over the last 50 years, Waratah has always been Built To Work® – supporting its customers, so they can outsmart and outperform the others.

“We’ve had great experiences with Waratah,” said Reid Lind, owner of G.R. (Mac) Lind Logging Ltd., Princeton, British Columbia. “You know what you’re getting when you buy it. For us, it’s the industry standard.”

Established in 1973 in Tokoroa, New Zealand, the company manufactured a delimber-feller-buncher with a four-roller fixed head to meet local loggers’ heavy-duty delimbing needs. Following that innovation, a red grapple processor manufactured for the Canadian markets marked the start of the 600 Series line. It cemented Waratah’s place as the original red head in the industry.

Today, Waratah’s full line of harvesting, processing and felling heads are used in a variety of logging applications from cut-to-length hardwood harvesting at the stump, to processing on a landing, felling on steep slopes or debarking on plantations.

“Waratah heads are designed well, tested well and built well,” said Pasi Volotinen, managing director of Waratah OM, Finland. “We are always aiming for best-in-class. We are happy when our customers are feeling good in the forest.”

Waratah continues to build on its past to innovate for the future – manufacturing more productive heads, engineering products with parts that don’t quit and working to earn each customer’s trust every day.

“Waratah’s legacy is about taking care of the customer, building a superior product, and improving it with each series,” said Robert D’Agostini, president and CEO of J&R Logging Inc., Fair Play, California. “We bought our first Waratah head in 2005, and we love them.”

-

That’s a remarkable amount of work hours for a single machine, the Norcar 600 owned by Erkki Rinne is taken well care of, it even has the original Diesel engine.

-

Kieran Anders is a forestry contractor working in the lake district. His work involves hand cutting and extracting timber using a skidder and tractor-trailer forwarder.

-

It is not possible to eliminate chain shot, but there are simple steps that can be taken to reduce the risk.

-

Arwel takes great pride in the fact that the mill has no waste whatsoever, “the peelings are used for children’s playgrounds, gardens and for farm animals in barns in the winter and the sawdust has multiple uses in gardens and farms as well.

-

Timber hauliers need to encourage young blood in, and also look after the hauliers we have, we need make the sector a safe and positive place to work.

FIND US ON

Related Posts

Forest Machine Magazine is written and edited by a forest professional with over 40 years hands on experience. We are dedicated to keeping you informed with all the latest news, views and reviews from our industry.

To support us you can subscribe to our bi-monthly magazine which is delivered to your door from only £30 per year.

Subscribe here

#homeoflogging #writtenbyloggersforloggers #loggingallovertheworld

-

1 Year Subscription£0.00

1 Year Subscription£0.00 -

2 Year Subscription£0.00

2 Year Subscription£0.00 -

Issue 38£6.00

Issue 38£6.00 -

Sustainable Logging: Powering The Planet T-Shirt£17.50 – £20.00

Sustainable Logging: Powering The Planet T-Shirt£17.50 – £20.00 -

Sustainable Logging: Powering The Planet Hoodie£33.00 – £36.00

Sustainable Logging: Powering The Planet Hoodie£33.00 – £36.00