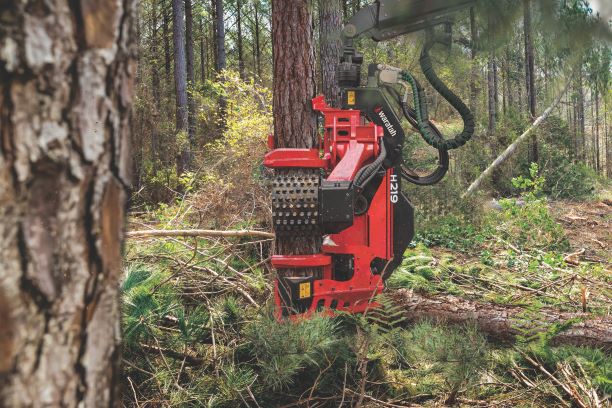

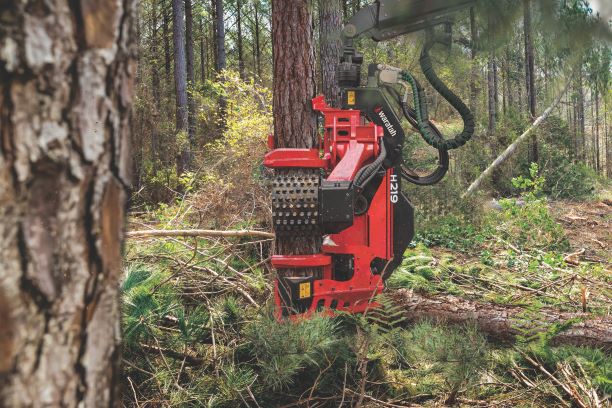

Waratah Forestry Equipment announces the new H219 and H219X harvester heads

Forestry Equipment has introduced two new models to its 200 Series line: the H219 and H219X harvester heads. Primarily built for late thinning or final felling, the new models have a variety of features for added uptime in harvesting, processing and debarking applications.

“The robust Waratah H219 and H219X heads define high capacity two-roller productivity,” said Brent Fisher, product marketing manager for Waratah. “Whether you’re in final felling or variable diameter late thinning in mixed stands, crooked hardwood or debarking applications, the new models deliver versatility with durability, performance and serviceability features our customers expect.”

Punched-up productivity

The H219, weighing in at 1,970 kg (4,343 lb.), or the H219X, at 2,050 kg (4,519 lb.), can efficiently handle large-size wood in final felling or late thinning applications – including hardwood or softwood – and eucalyptus debarking. The narrow head design lends itself to improved visibility in thinning applications, while the two-roller geometry design provides excellent handling of variable diameters and challenging tree forms up to 750 mm (29.5 in.) in diameter.

Available configuration options promote productivity in processing applications. These include longer upper-delimb arms, top saw and find-end sensor, which are available for faster processing of logs from the ground. Furthermore, the new length measuring unit has improved geometry and consistency for more precise measurements – reducing measuring loss and reversals.

Additionally, the H219 and H219X are equipped with the new SuperCut 100S saw unit which features new improvements to usability and serviceability. One highlight of the SuperCut 100S is the improved chain tensioning system, which extends saw bar and tip life while reducing chain jump-off. The saw also has new mechanical bar locking – making saw chain changes easier and providing more flexibility for motor sizing and wide-tail saw bars for broader application suitability.

“The H219 and H219X are such great heads for large wheeled or tracked machines – handling so many different large diameter applications,” Fisher said. “With their versatility and power, these really are great heads for tackling the tough jobs.”

Dependable durability

With uptime being critical to any operation, the H219 and H219X have a variety of improved features that enhance durability. The configurations include new optional HD feed roller guards for durability in thick understory or rough terrain. A heavy-duty (HD) tilt frame option is available for tracked applications, and it is standard on the H219X.

Improved hose routing along with new guarding protection on both the exterior and underside of the head help extend hose life. The new configuration helps reduce limb interference with hoses, cylinder and motor fittings, while feed motors have new anti-cavitation protection.

Likewise, the optional top saw now has a more integrated design improving durability and serviceability. The new design features guarding on the underside to keep splinters and debris away.

Additionally, the new measuring arm design features a larger cylinder and pins, higher contact force and increased shock resistance while a larger and more aggressive measuring wheel expertly handles trees with thick bark.

Increased uptime

Simplified servicing extends operational time to increase productivity on the job. Highlights of the H219 and H219X include a new valve cover and more easily accessible service points for quicker access – reducing servicing time.

Likewise, new hose bulk-heads improve access with hose connections externally accessible for quick changeouts.

The Waratah H219 and H219X are currently available to customers in Europe, the United States, Canada, Australia, New Zealand, Russia, Asia Pacific, Brazil and Latin America.

For more information about Waratah, please visit Waratah.com or contact Sarah Larson at slarson@mindfirecomm.com.

Waratah Forestry Equipment, headquartered in Rotorua, New Zealand, has served the global forestry industry for 45 years, manufacturing harvesting, processing and heads as well as harvester and forwarder cranes in its state-of-the-art facilities in New Zealand and Finland. The company’s extensive support and parts distribution network, rigorous global application testing, advanced manufacturing systems and sophisticated quality measures deliver customers with durable and reliable forestry equipment that is Built to Work.

Forest Machine Magazine is written and edited by a forest professional with over 40 years hands on experience. We are dedicated to keeping you informed with all the latest news, views and reviews from our industry.

To support us you can subscribe to our bi-monthly magazine which is delivered to your door from only £30 per year.

Subscribe here