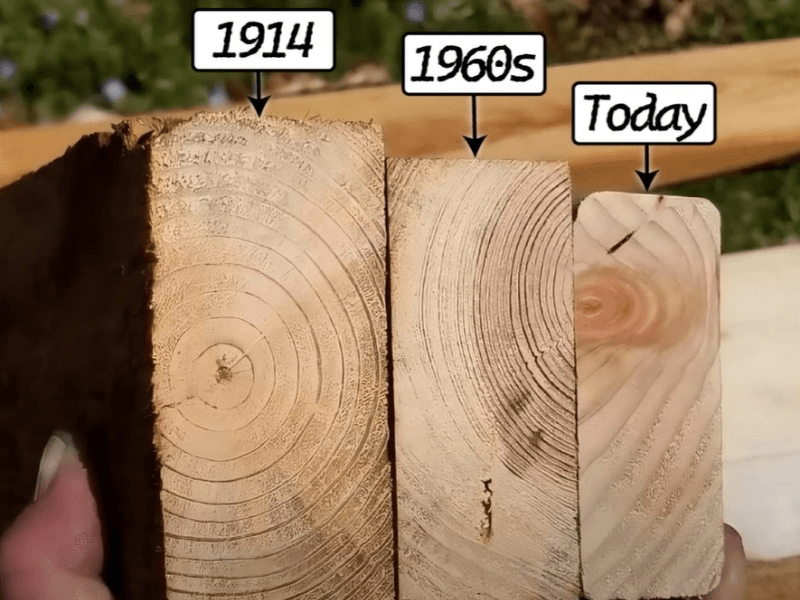

The Shrinking 2″×4″ Timber Sizes – The History Behind The Mystery of the decrease.

The Shrinking 2″x 4″-Sue wanted to build her first DIY project – the ultimate chicken coop. When she started to build the frame, she realised her 2×4 lumber is actually only 1-1/2 inches by 3-1/2 inches.

Most people are shocked to find out that a 2×4 is not actually two inches by four inches. Oh the scandal! But, it’s true! The nominal size of a 2×4 refers to its rough-cut dimensions, not its actual measurements.

-

That’s a remarkable amount of work hours for a single machine, the Norcar 600 owned by Erkki Rinne is taken well care of, it even has the original Diesel engine.

-

Kieran Anders is a forestry contractor working in the lake district. His work involves hand cutting and extracting timber using a skidder and tractor-trailer forwarder.

-

It is not possible to eliminate chain shot, but there are simple steps that can be taken to reduce the risk.

-

Arwel takes great pride in the fact that the mill has no waste whatsoever, “the peelings are used for children’s playgrounds, gardens and for farm animals in barns in the winter and the sawdust has multiple uses in gardens and farms as well.

-

Timber hauliers need to encourage young blood in, and also look after the hauliers we have, we need make the sector a safe and positive place to work.

FIND US ON

Related Posts

The Transformation of Lumber Dimensions

The dimensions of lumber, particularly the 2×4, have evolved significantly over time. This article aims to elucidate the historical shifts in lumber sizing and the reasons behind these changes.

Historically, more than a century ago, the manufacturing of dimensional lumber in the United States was predominantly carried out by local mills. These mills produced rough lumber characterized by inconsistent widths and non-standard dimensions. Consequently, builders were required to plane the boards on-site to accommodate their specific construction needs. The industry faced challenges related to varying regional interpretations of standard dimensions, along with disparate wood types and dimensions across different manufacturers. This lack of uniformity contributed to the ambiguity surrounding the term 2″ by 4,” creating confusion for both buyers and sellers throughout the United States.

Life before lumber size standards

Before the standardisation efforts in the construction industry, lumber mills and builders sized lumber to the beat of their own drum.

Builders frequently placed orders for custom-sized pieces of wood tailored to meet the specific requirements of their projects. This pre-industrial approach granted builders greater control over their endeavours by allowing for the accommodation of unique specifications; however, it also introduced several challenges.

The emphasis on customisation resulted in extended lead times and increased complexity within the manufacturing process. Builders were required to await the completion of their tailored orders before initiating construction activities. Consequently, manufacturers had to navigate a complex system to produce a diverse array of specifications, sizes and shapes of wood pieces based on individual requests.

Slimmer 2×4’s – How Shipping Costs Changed Lumber Size

Wood manufacturers faced a significant challenge in the late 1800s when forests near major cities were depleted, necessitating the shipping of lumber over longer distances. However, the exorbitant costs of railroad shipping, often double the price of the lumber itself, prompted manufacturers to find innovative solutions.

To minimize wastage and reduce transportation weight, manufacturers recognized the advantage of planing lumber at the mill prior to shipping, rather than performing this process on-site.

The inauguration of the Panama Canal in 1914 further intensified competition, as it enabled west coast mills to access east coast markets. At that time, ocean shipping rates were predominantly dictated by volume, prompting wood manufacturers to explore methods to decrease shipment volumes. Consequently, they commenced the production of thinner lumber while still designating it as a “2 by 4.”

Economic Factors Influencing Lumber Sizes

During the Great Depression, the lumber industry experienced a substantial decline in demand that persisted for approximately ten years. This reduction in demand significantly affected the standardization of lumber sizes, as the industry’s efforts to revive demand presented a formidable challenge.

However, the onset of World War II marked a pivotal shift; there was an exponential increase in the demand for lumber to support the war efforts globally. This surge re-emphasized the focus on standard lumber sizes. To accommodate this heightened demand, manufacturers adjusted the dimensions of their lumber. This strategic modification allowed them to utilize raw materials more efficiently and minimize waste. Such optimization not only enabled them to meet market demands effectively but also bolstered their overall profitability.

Lumber Size Standards – Forest Products Laboratory to The Rescue

To address the growing confusion and dissatisfaction among retail dealers, the Department of Agriculture took action in 1919 by establishing the Forest Products Laboratory. This laboratory had a clear mission: to investigate suitable dimensions for lumber that could be adopted as a national standard.

Following an extensive investigation involving 75 mills, it was concluded that joists and studs measuring 1-5/8 inches by 3-5/8 inches are optimal from both economic and functional perspectives. The researchers observed that reducing the dimensions of traditional 2×4 lumber did not compromise its structural integrity, as the additional weight was found to have a negligible impact on strength.

As time progressed, further modifications were implemented regarding the dimensions of the 2×4. These alterations were influenced by various factors, including specifications related to moisture content, shipping costs, and evolving industry standards.

The Modern 2×4 – The Main Player in the Evolution Of Standardized Lumber Sizes

Now that we’ve explored the evolution of lumber dimensions and the factors that have shaped the modern 2 by 4, it’s clear that this seemingly simple piece of wood carries a rich history. From customized sizing in pre-industrial times to national standardization efforts, the dimensions of a 2 by 4 have been influenced by economic factors, shipping costs, and efficiency considerations.

We often take for granted how much time and effort it took to go to a manufacturer and purchase lumber that is standardised. So while a modern-day 2×4 may not measure exactly two inches by four inches, it still serves its purpose as the backbone of most construction projects.

Next time you pick up a piece of lumber or embark on a construction project, take a moment to appreciate the journey that led to those familiar measurements.

FAQs

Why are modern-day 2x4s smaller than their name suggests?

The modern-day dimensions of a 2×4 are smaller due to historical practices and practical considerations. Thinner pieces of wood were favoured over time to reduce shipping costs and increase efficiency in transportation. These dimensions eventually became standardised to strike a balance between cost-efficiency and structural integrity.

Can I still find custom-sized lumber if needed?

While standardised dimensions are prevalent in the industry today, it is still possible to find custom-sized lumber if needed. Local sawmills or speciality suppliers may offer options for customised cuts or larger dimensions beyond what is commonly available at retail stores. However, keep in mind that custom sizing may come with additional costs and longer lead times.

Sign up for our free monthly newsletter here

Contact forestmachinemagazine@mail.com to get your products and services seen on the world’s largest professional forestry online news network.

#homeoflogging #writtenbyloggersforloggers #loggingallovertheworld

Written by loggers for loggers and dedicated solely to the equipment used in forestry operations.