Using more wood in hospitals could be better than using concrete, stainless steel and plastics as it has better bacterial resistance

Wood in hospitals- When you think of a hospital, you might picture materials like concrete, stainless steel, or plastic. However, researchers at the University of Oregon aim to make wood—often overlooked in healthcare settings—more common in these environments.

-

That’s a remarkable amount of work hours for a single machine, the Norcar 600 owned by Erkki Rinne is taken well care of, it even has the original Diesel engine.

-

Kieran Anders is a forestry contractor working in the lake district. His work involves hand cutting and extracting timber using a skidder and tractor-trailer forwarder.

-

It is not possible to eliminate chain shot, but there are simple steps that can be taken to reduce the risk.

-

Arwel takes great pride in the fact that the mill has no waste whatsoever, “the peelings are used for children’s playgrounds, gardens and for farm animals in barns in the winter and the sawdust has multiple uses in gardens and farms as well.

-

Timber hauliers need to encourage young blood in, and also look after the hauliers we have, we need make the sector a safe and positive place to work.

FIND US ON

Related Posts

Their findings suggest that wood exposed to water can resist microbial growth after a brief period of exposure. In their study, wood samples showed lower levels of bacterial abundance compared to a plastic control enclosure that remained empty.

“People generally perceive wood as unhygienic in medical settings,” said Mark Fretz, an assistant professor and co-director of the UO’s Institute for Health in the Built Environment, who is also the principal investigator of the study. “But wood transfers microbes at a lower rate than other, less porous materials like stainless steel.”

Numerous studies back up these properties of wood. The University of Oregon-led research team, which includes scientists from the Salk Institute for Biological Studies in San Diego and Portland State University, sought to explore what occurs when wood becomes wet and then dries.

A recent study published in *Frontiers in Microbiomes* revealed findings about the impact of moisture on surface microbes and the emissions of volatile organic compounds from mass timber.

Mass timber, an engineered wood material, is gaining popularity as an alternative construction material in the U.S. However, its use in health care facilities is limited. This limitation is partly due to the slow adaptation of stringent building codes, as noted by Fretz. Additionally, there are widespread misconceptions regarding wood and its association with pathogens.

“We aimed to investigate how mass timber performs under the typical conditions found in health care settings,” explained Gwynne Mhuireach, a research assistant professor at the University of Oregon. “In hospitals and clinics, germs are always present, and surfaces are occasionally exposed to moisture.”

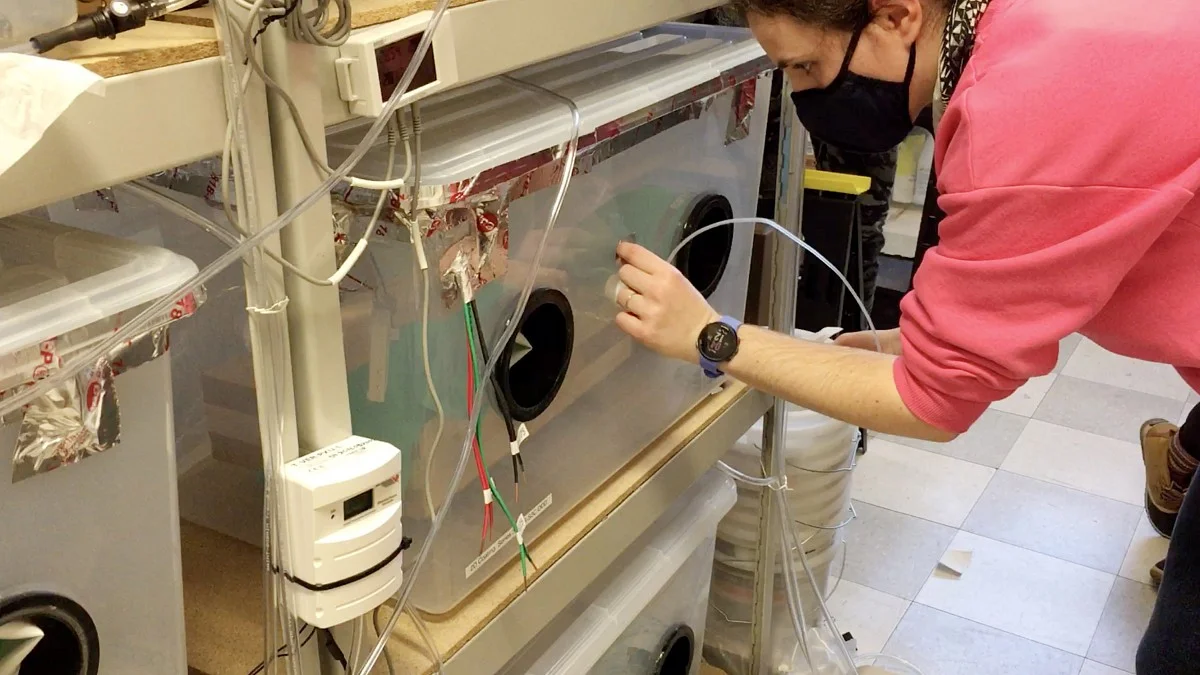

For the experiment, blocks of cross-laminated timber were placed in disinfected plastic boxes to create a controlled microenvironment with specific temperature and humidity conditions. To replicate a health care setting, air was filtered and exchanged at rates comparable to those required by hospital regulations.

A recent study published in *Frontiers in Microbiomes* revealed the impact of moisture on surface microbes and the emissions of volatile organic compounds from mass timber.

Mass timber, an engineered wood material, is gaining popularity as an alternative construction material in the U.S. However, its use in healthcare facilities remains limited. This limitation is partly due to the slow adaptation of stringent building codes, as noted by Fretz. Additionally, there are widespread misconceptions about wood and its association with pathogens.

“We aimed to investigate how mass timber performs under typical conditions found in healthcare settings,” explained Gwynne Mhuireach, a research assistant professor at the University of Oregon. “In hospitals and clinics, germs are always present, and surfaces are occasionally exposed to moisture.”

For the experiment, blocks of cross-laminated timber were placed in disinfected plastic boxes to create a microenvironment with controlled temperature and humidity. The air was filtered and exchanged at rates comparable to those required by hospital regulations, replicating a healthcare setting.

The team sprayed the blocks with tap water, inoculated them with a cocktail of microbes commonly found in hospitals, and took samples over a four-month period. An empty plastic box was used as a control.

Researchers compared coated and uncoated wood samples under three types of water spray conditions: once, daily for a week, and daily for four weeks.

The study’s results showed that wood is effective at inhibiting bacteria and provided insights into wetting that could inform future research and development, according to Mhuireach.

The empty plastic control box had a higher abundance of viable microorganisms than the wood samples, except during the first 14 days after inoculation.

Wetting the wood blocks decreased the number of viable bacterial cells, with no significant difference observed between the coated and uncoated specimens. The microbial composition during wetting mirrored the common bacteria found in tap water rather than the hospital pathogens introduced by the research team.

This research was the first to examine the relationship between microbial communities on cross-laminated timber surfaces and the emission of volatile organic compounds (VOCs) under dry and wet conditions, Mhuireach noted.

VOCs are chemicals that quickly disperse in the air, producing various odours such as those from perfumes, mould, or the “new car smell.” While some VOCs pose health risks, others can be beneficial.

Wood can emit compounds known as terpenes, many of which have pleasant scents and can inhibit the growth of microorganisms. Mhuireach reported that VOC emissions plateaued after wetting, which the team interpreted as indicating a slight increase, despite an overall downward trend.

This study represents a significant step forward in the University of Oregon’s efforts to encourage the use of mass timber in healthcare facilities.

This initiative began in 2020, supported by a Wood Innovations grant from the U.S. Department of Agriculture, as noted by Fretz. This funding enabled the formation of a focus group comprising architects, engineers, and experts in healthcare building codes. The grant also supported the recent research on wetting.

Through collaboration with the TallWood Design Institute, a joint project of the University of Oregon and Oregon State University, Fretz has been promoting the production and utilisation of mass timber, including materials manufactured in Oregon.

Construction using engineered wood made from cross-laminated layers of veneer or lumber began in Europe in the mid-1990s and is now expanding in the U.S.

Mass timber is stronger per pound than steel or concrete and has a smaller carbon footprint. Exposed wood is also linked to health and healing because it taps into our innate desire to connect with nature, Fretz explained.

This human inclination, often referred to as biophilia, extends beyond aesthetics; numerous studies have connected biophilic design to improved healthcare outcomes, including shorter hospital stays, quicker healing, and enhanced mental well-being.

Wood’s potential to inhibit pathogen spread may arise from its pores, which can trap bacteria, or from antimicrobial compounds that occur naturally within the wood. It may also be due to wood’s ability to absorb moisture.

Fretz mentioned that respiratory viruses released indoors travel in water droplets, and wood dries these droplets faster than plastic or stainless steel, leading to a reduction in the survival time of the virus. reducing virus survival time.

Contact forestmachinemagazine@mail.com to get your products and services seen on the world’s largest professional forestry online news network.

#homeoflogging #writtenbyloggersforloggers #loggingallovertheworld

Written by loggers for loggers and dedicated solely to the equipment used in forestry operations.