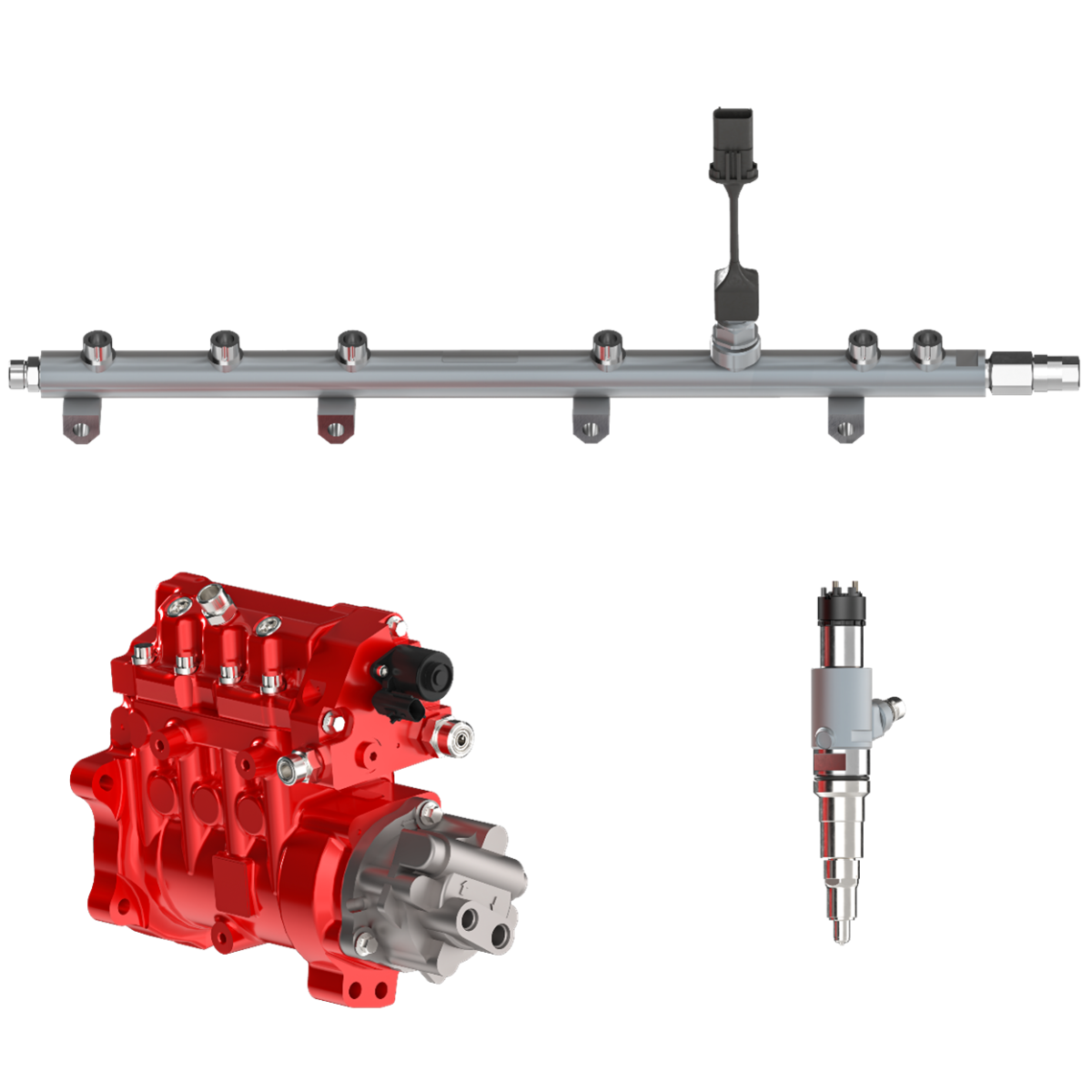

Cummins launches new Fuel System for Off-Highway Applications

Global power and technology leader Cummins Inc. (NYSE: CMI), is pleased to announce the launch of its new Fuel System designed specifically to meet the diverse needs of non-road, off-highway applications. This latest innovation from Cummins Components and Software (CCS), a part of Cummins’ Components business unit, promises to deliver unparalleled performance, scalability, and integration, setting a new standard in fuel system technology.

-

That’s a remarkable amount of work hours for a single machine, the Norcar 600 owned by Erkki Rinne is taken well care of, it even has the original Diesel engine.

-

Kieran Anders is a forestry contractor working in the lake district. His work involves hand cutting and extracting timber using a skidder and tractor-trailer forwarder.

-

It is not possible to eliminate chain shot, but there are simple steps that can be taken to reduce the risk.

-

Arwel takes great pride in the fact that the mill has no waste whatsoever, “the peelings are used for children’s playgrounds, gardens and for farm animals in barns in the winter and the sawdust has multiple uses in gardens and farms as well.

-

Timber hauliers need to encourage young blood in, and also look after the hauliers we have, we need make the sector a safe and positive place to work.

FIND US ON

The new Fuel System is designed with the customer in mind, with a wide range of engine platforms, ensuring smooth integration and optimal performance. The Fuel System is designed for seamless integration with customers’ engine offerings. The pairing of the common rail system hardware with specific Fuel Systems controls caters to various off-highway applications such as construction, mining, and power generation. The system has the potential to be applied across other engine ratings with minor fuel system tailoring on the pump, injector, and rail. Furthermore, the system’s adaptable design enables it to be used in other industrial sectors.

Advancing durability and system efficiency

Cummins has made significant improvements to the common rail Fuel Systems to ensure better performance, fuel economy, and durability. The system also boasts rail pressure up to 2200 bar and with built-in protection up to 2600 bar, while the high-capacity pump delivers high flow rates over 500 pph (pounds per hour) at 1800 bar.

“Our advanced engineering features, such as the enhanced injector nozzle spray holes and special coating on high-pressure fitting ports, ensure improved durability and performance,” said James C Simonton, Director, Advanced Engineering & Technical Leadership, Cummins Components and Software.

The Fuel System is built on Cummins’ proven heavy-duty Oil Lubricated Pump (OLP) platform, which brings years of production experience and field validation. This makes the system highly reliable and capable of meeting durability targets of up to 20,000 hours, depending on application duty cycles.

Lowering Total Cost of Ownership (TCO) through serviceability, performance and customer-centric design

Customer-focused design is at the core of the Fuel Systems development at Cummins. The new Fuel System enables customers to meet stringent leading and lagging emissions standards (Stage 2, Tier 4, and global emissions), while enhancing performance and fuel economy. The system’s critical pump components, such as Low Pressure Pump (LPP) and Inlet Metering Valve (IMV), are all serviceable.

“Our Fuel Systems are engineered to provide customers with a lower TCO by reducing maintenance costs and improving uptime,” says Piyumani Karunaratna, Director of Marketing, Cummins Components and Software.

Availability and manufacturing

Developed through global collaboration across teams in the United States, India, and China, the system will be manufactured at a Cummins facility with cutting edge sub-micron machining and world class cleanliness. The new Fuel System products are expected to be available later in 2025.

Sign up for our free monthly newsletter here

Contact forestmachinemagazine@mail.com to get your products and services seen on the world’s largest professional forestry online news network.

#homeoflogging #writtenbyloggersforloggers #loggingallovertheworld

Written by loggers for loggers and dedicated solely to the equipment used in forestry operations.