Fuelwood (Warwick) Ltd have always been focused on firewood, timber conversion and forestry machinery. A 30 acre site at Claywood makes for an ideal central location for supporting customers throughout the UK.

Fuelwood (Warwick) Ltd are the UK importers and main dealers for: Heizohack Wood Fuel Chippers; GROS Wood Chip Blowers; FTG-Mowi Timber Cranes and Trailers; FTG-Moheda Timber Cranes and Trailers; Avesta Vagnen Timber Cranes and Trailers for ATV’s; Plaisance Forestry Mulchers; AMR Log Splitters and Circular Saws; Japa Firewood Machines; Vepak Automatic Firewood Bagging Systems & Lucas Mill Mobile Sawmills. The company also designs and manufacture their own brand of machines for high production kindling wood and firewood for both packaged and bulk loads.

Here we take a brief look at Heizohack, AMR, Japa and the Lucas Mill Mobile Sawmills:

Heizohack

Heizomat GmbH of Gunzenhausen in Germany are one of the leading manufacturers of professional wood-chippers under the Heizohack brand, and they have a pedigree in the wood-chip business few others can match. Founder of Heizomat Robert Bloos built the first automatic discharger system for wood-chips in 1982. The idea behind it was to use wood from his own forest with the same ease as he would fossil fuels. In the beginning the discharger system was only to supply the boiler with wood-chips for his own agricultural business, yet more and more people showed their enthusiasm for the “Heizomat”.

The current range of Heizohack biomass quality chippers now runs from the HM4-300 hand fed chippers with a 30cm feed height to the huge HM 14-860 range of crane fed chippers with up to 121cm feed width and 86cm feed height. These are seriously big chippers and have to be seen in action to be believed. Power supplies range from PTO, auxiliary engines or direct drive via the 440hp truck engine on the Mercedes Actros truck mount versions.

Fuelwood (Warwick) Ltd were the first UK Heizohack distributor appointed in 2004. Since then they have seen a huge growth in the sale of these exceptional machines. They are clearly passionate about Heizohack and keen to demo them on any occasion.

Premier Tree Care & Conservation Ltd

David Stevens of Premier Tree Care & Conservation Ltd of Ashford in Middlesex runs his family business that has been operating for over 50 years. David and his team provide a wide range of arboricultural, landscaping and gardening services across Surrey and Middlesex. In particular they do a lot of commercial site clearance for developers and contract chipping.

David started his Heizohack journey with a HM8-400 hand fed chipper, but after 12 months he realised the benefit of moving to a larger crane fed machine. He upgraded to a HM8-400K which he powers with his Valtra tractor. David describes his Heizohack machine as ‘Simply Brilliant’. The HM8-400K makes light work of all wood waste, such as beams, logs, blocks or branches so is perfect for David’s site clearance work. The in-feed is 400mm high x 708mm wide so it is easy to feed and can be loaded with multiple pieces at the same time. Even trunks right up to the maximum 400mm diameter can be processed with relatively little power needed. David sells the wood-chip he collects for biomass and to landscape gardeners and local authorities.

“The Heizohack is a very good chipper producing the right size and quality of chips” says David. “It’s a solid, robust machine of typical German quality. Spares are readily available, not too expensive and easy to replace so we can maintain it ourselves”.

Oliver Edwards

In contrast Oliver Edwards of Westermill Farm in Somerset uses his Heizohack mostly on his own 500 acre working farm where he also runs a camp-site and has six self-catering cottages. They have been actively planting trees since the 1960’s but fifteen years ago they planted 18,500 hardwood trees and now use chippings from their own trees to fuel a biomass system which heats the farm house, annexe, camping toilet block and the holiday cottages. “We are very environmentally minded and combine conservation and tourism” says Oliver, “Biomass is great for us, previously we used a lot of electricity especially to heat the cottages during the winter. Now we heat them 24 hours a day which reduces the deterioration of the properties yet costs much less overall”.

Oliver was keen to have a single person operation chipper/trailer set up that would cover a wide range of situations around the farm. Although Heizohack produce a combined machine, it’s based on the large HM8-400 chipper which didn’t suit Oliver’s needs. Oliver decided to create his own based around the smaller Heizohack HM6-300 which perfectly met his varied requirements. He has now designed and built a custom chipper, crane and tipper trailer combination which he affectionately calls CHIPZILLER.“Before, when we used to go chipping it needed two men and two tractors and trailers, now with CHIPZILLER one man can do the same work with a lot less mess” says Oliver. The Heizohack was chosen because of its good reputation for reliability and uniform wood-chip, which was essential for his biomass application.

Ken Tongue Agriculture Ltd

Ken Tongue Agriculture Ltd of Surrey is a keen Heizohack man and now on his second machine having bought his latest HM14-860KTL. Chipping has transformed Ken’s business from farm and grass contracting in the summer and little work in the winter, to now being busy all through the winter months producing biomass wood chip. He mostly does this from locally sourced cordwood for customers who demand high quality chip. Ken’s wood-chip now finds its way into many places including Heathrow airport (which incidentally uses 25,000 tonnes of wood-chips a year), hospitals, schools and private homes.

Ken uses a Valtra tractor to power his HM14-860 which can produce over 50 tonnes an hour when chipping dry timber, and also in three chip sizes with a simple change of screen. “There’s no point in having the best output if the chip quality is not right”, said Ken. “The

Heizohack is easy to use and maintain and if anything goes wrong I can usually fix it myself and get straight back to work”.

-

That’s a remarkable amount of work hours for a single machine, the Norcar 600 owned by Erkki Rinne is taken well care of, it even has the original Diesel engine.

-

Kieran Anders is a forestry contractor working in the lake district. His work involves hand cutting and extracting timber using a skidder and tractor-trailer forwarder.

-

It is not possible to eliminate chain shot, but there are simple steps that can be taken to reduce the risk.

-

Arwel takes great pride in the fact that the mill has no waste whatsoever, “the peelings are used for children’s playgrounds, gardens and for farm animals in barns in the winter and the sawdust has multiple uses in gardens and farms as well.

-

Timber hauliers need to encourage young blood in, and also look after the hauliers we have, we need make the sector a safe and positive place to work.

AMR

The French may not automatically be associated with world class engineering and design but that would be wrong. In fact they have a history of excellence in engineering any country could be proud of. The diesel engine, the helicopter, the bicycle, the parachute, the drum brake, Concorde, the outboard motor, Westminster Bridge, the Eiffel Tower, the submarine, the dry cell battery, reinforced concrete and the guillotine – all French inventions and the list goes on. Today this excellence continues with firewood production machinery from AMR.

AMR is located in Elsenheim near the Rhine river and the German border in the Alsace region of France, a region that has seen both Germany and French control over the centuries. The company Ateliers Mecaniques du Ried was formed in 1984 by some former employees of the Heywang agricultural machine company and they started forestry winches and log splitters. Some 20 years later the company was bought by Robert Heissler who gave it the name we know today, AMR. Under Robert’s leadership AMR focused its efforts on developing a world class range of machinery for firewood production. The core ranges being Log Splitters, Circular Saws and related hauling and handling equipment.

In 2015 AMR changed hands again, this time being bought by Unterreiner Forstgerate GmbH of Germany, who are a major distributor of forestry equipment across Europe. For Gert and Manuela Unterreiner who jointly head up this highly impressive business, this is their first venture into the world of manufacturing. Their German passion for selling quality and safety is a perfect match for the AMR range which now features heavily in their growthplans.

Innovation is at the heart of AMR design, tackling the age old problems of producing consistent firewood logs from an inconsistent raw material in an efficient and safe way. AMR’s products are very much the bread and butter products for low to medium volume firewood producers. Specifically for those who don’t wish to invest in large plant requiring consistent quality cord timber, but whose timber maybe from tree surgery or mixed sources and thereby requiring a much more flexible processing option. Their splitters range from 6 tonnes to 28 tonnes and offer a huge variety of operating options. From free standing vertical or horizontal varieties to portable or trailable splitters and even ones that can be mounted directly onto the front loader of a forest crane. These are impressive machines capable of tackling the most awkward of splitting tasks with relative ease.

Perhaps even more impressive is the AMR range of circular drum saws. The Quatromat was first introduced in 2012 and was a complete breath of fresh air to the industry. Circular saws are great, they cut faster and for longer than chain saws, but open blades of any sort are dangerous and the Quatromat addresses safety in a way never seen before. In fact its design almost defies you to spot the saw blade let alone come in contact with it. With so many people in our industry at risk of injury every year it is truly the right way to go.

Joy Lane & Sons of Uttoxeter in Staffordshire specialise in producing and selling air dried firewood as well as providing tree surgery, onsite milling services, creating bespoke log stores and selling Maximus Wood Fired Ovens. They supply firewood across the UK with regular truck loads up to Scotland and across England and they service garages, firewood merchants, garden centres, coal merchants, shops and domestic users. “Firewood sales have gone through the roof” says Joy, “Our investment in AMR machinery has increased our production by a third – it takes less time to produce more product”.

The business has previously used large semi-auto-matic firewood processors but these didn’t suit all of the timber coming in from their surgery work or other local sources. They invested in a 28 Tonne AMR Log splitter, an AMR Quatromat and an AMR Billet Bundler from Fuelwood “We always buy from Fuelwood” says Joy, “Reliable machines and easy to deal with nice people. We even help out at their Open Days demonstrating equipment”.

Everyone in their team of 5 full time and 2 part time staff can use the AMR machines. Joy adds, “The Splitter and Quatromat are so safe and easy to use, no danger of open blades or kick back, you just drop the timber lengths in the Quatromat and out pops the perfect length logs”. With four timber input chambers the Quatromat has an impressive output potential and allows for continuous working. The AMR splitter and AMR Quatromat seems to have solved all their issues with odd shaped timbers and the AMR Bundler makes the packaging of 1 cubic metre bags a breeze. Joy who is passionate about not only the firewood quality but how it looks and presents loves the results. “Consistency is important as domestic customers want easy to light uniform wood nicely packaged. Some stack the firewood up around their burners so it’s on show and needs to be clean and presentable”.

Find Us On

JAPA

It won’t surprise you to know that there is a of lot of forest in Finland. According tothe Finish Forest Association it’s the most forestedcountry in Europe with around 75% of the total landmass forest. For every single Finn there is 420 acres offorest. Over 60% of all forestry is in private ownership.There are 632,000 privately owned forests and 14% ofall Finns own their own forest. Over half of these exceed300 acres in size. About fifty percent of all forests arepine, the rest being a mix of spruce, downy birch andsilver birch. It also won’t surprise you to know the Finnsknow a great deal about forest machinery and that theymake some of the very best in the world.

Laitilan Rautarakenne, known in the UK as Japa® was established by two brothers, Jari and Jarmo Paavola in 1977. Located in Laitilan Finland, they manufacture a wide range of agricultural and forestry machinery and equipment and their goal has always been to make forestry work easier and safer. Today Japa® is part of the Terra Patris Group which also own Palax & HakkiPilke (firewood processors), Selio & Finn-Marin (speed boats), Movax (piling machinery) and MetalPower (engineered metal products). Under Managing Director Henri Nurminen, Japa® are now one of the leading and most innovative of manufacturers in the Scandinavian forestry sector, with over 200 retailers worldwide. Japa firewood processors are renowned for their power to size and price ratio. One of Japa’s key export markets is the UK. Through their distributor Fuelwood they have established an enviable reputation for making the production of firewood easier, faster and safer. Japa® machines are now used widely throughout the UK with happy customers ranging from small woodland owners to professional firewood producers.

South Coast Fencing

Andy Fitzgerald started South Coast Fencing 30 years ago as a fencing contractor. Now located in Winchester, Andy’s business supplies and installs Fencing, Decking, Gates/Automated Gates and sells seasoned logs and kindling all year round. Fencing is the main part of their business – and they offer bespoke fencing to the customer’s specification – the customer can bring pictures in and they can make it to meet their requirements.

However, they decided to invest in the firewood side of their business and after much investigation into the options decided that a Japa® 435 from Fuelwood was the best machine for them. They also invested in a second hand Kindling machine and more recently in a Kiln which runs off the waste from the log cutting. The log side of the business trades under the brand UniLogs and in their first year with the Japa® 435 they have split and sold over 200 tonnes of locally sourced timber into logs with demand increasing as they become better known for firewood. “The Japa® 435 is easy to work, reliable and safe to use – you cannot do anything unless it is in a safe mode, all moving and working parts are covered and we use a joystick to control it” says Andy.

Alex Calvert

Alex Calvert of Whithorne Estate owns a Japa® 355. His business partner breeds polo ponies and he is developing a commercial woodland. This is a new venture and as Alex says “It’s a long term plan, we have been clearing areas and replanting a mixture of oaks and evergreens, it’s an investment for our children”. They received a Rural Agency Grant to help purchase new machinery but faced the challenge of finding the right equipment for their needs. Here Fuelwood really came to the rescue and advised on every aspect of both the firewood processor and trailer and deck they would need. Having no prior experience themselves Fuelwood’s advice and support with specification for the grant application ensured they got the right machinery. The Japa® 355 was chosen along with a Mowi trailer.

The Japa® 355 is very compact yet highly capable firewood processor and an ideal purchase for a new commercial firewood business. It’s very early days for Alex, but he plans to sell firewood into his local market.

Ian Firewood & Kindling

Ian Pounder of Ian Firewood & Kindling is a long term Japa® fan, he has been using them since 1997. It’s a small familybusiness with just 3 staff. They buy in timber, cut itup, net it, bag it and sell it. They have one largecustomer Bagnalls whosell nationwide under the

Fuel Express brand. They also sell logs and kindling to local garages and households. Ian has always bought Japa and he always buys them from Fuelwood. “I looked around and found Fuelwood were better. They send out parts straightaway and I can ring if a problem and will be given advice and resolve any problems quickly.” says Ian. They currently have a Japa® 700 firewood processor because he finds a circular blade far easier to maintain, and a Japa® 600 saw bench. “Japa® machines come out on top – reliable, safe to use, easy to maintain. We have tried other machines, but Japa® are the best.” concludes Ian.

Lucas Mill

We tend to associate Australia with sun-drenched beaches and huge areas of dusty landscape known as the ‘outback’. However Australia actually has 125 million hectares of forest, equivalent to 16% of its total land area. Given Australia is 32 times larger than the UK, this means its forestry covers an area 5 times that of the whole of the UK. That’s a lot of trees! So it is hardly surprising that Australia has a large and well-developed forestry industry which generates over £13bn (UK is £8.5bn) in revenue and employs 66,000 people.

The Lucas family established Lucas Mill Pty Ltd in March 1994. Their aim was to provide landholders and small-medium forestry operators with a timber-milling machine that was simple to operate, affordable without compromising quality and versatile with regards to its ability to be used in any environment. Commencing operations in a small farm shed with limited expectations, it came as a huge surprise when orders for over 50 machines were placed in the first month of manufacturing. Demand continued to grow at a substantial rate.

The success of the Lucas Mill is quite simply down to the brilliance of its design. Not only is it easily portable into otherwise inaccessible locations and can be quickly set up on uneven terrain, but it’s the simplicity of its operation and the consistent accuracy, speed and finish of the cut that never fails to impress. It inspires confidence and encourages the conversion of felled timber into high value beams, boards and slabs.

Lucas Mills are used by a variety of businesses including; tree surgeons, timber wholesalers, wood workers, wooden building manufacturers, fencers and furniture manufacturers. Its versatility is only limited by the imagination of the user, and there are some very imaginative users.

J Hubbard and Son Ltd

J Hubbard and Son Ltd of Balsall Common near Coventry supply and erect a large range of quality fencing, gates and doors specialising in bespoke products for domestic, equine and agricultural markets. For a company that’s just celebrated 100 years in business, they have a real focus on the future. Charlie Hubbard, great grandson of the founder, is the latest generation of the family to take up the reins. He explained: “Fencing has been a big focus for the business over the past 20 years. We were just contractors but we set up a trade counter which is proving to be very successful and we’ve replicated it online with an eBay shop which generates a steady stream of new customers for fencing and agricultural tools.” They now supply garden panels, fence posts, fencing timbers, timber materials for sheds, stables and a wide range of fixings as well as Ritchie gates and livestock handling systems.

In 2016 Charlie purchased a Lucas Mill so they could start to mill timber from trees supplied by local tree surgeons. “This enables us to cut hardwoods and softwoods in varying sizes to suit“, says Charlie. “It’s great to be able to manufacture stunning green oak gates from local timber that would have otherwise just gone into the log trade”.

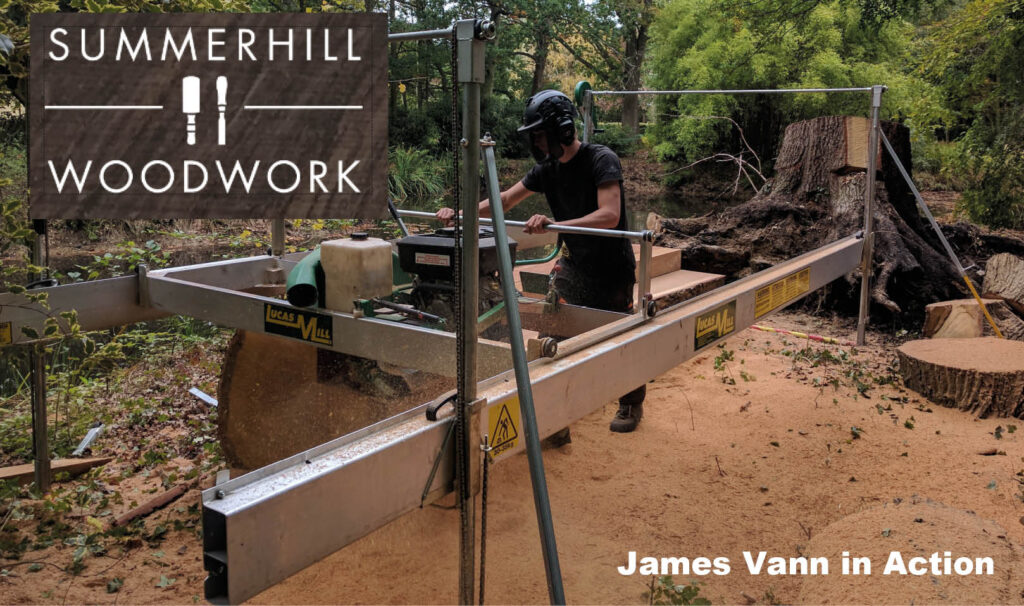

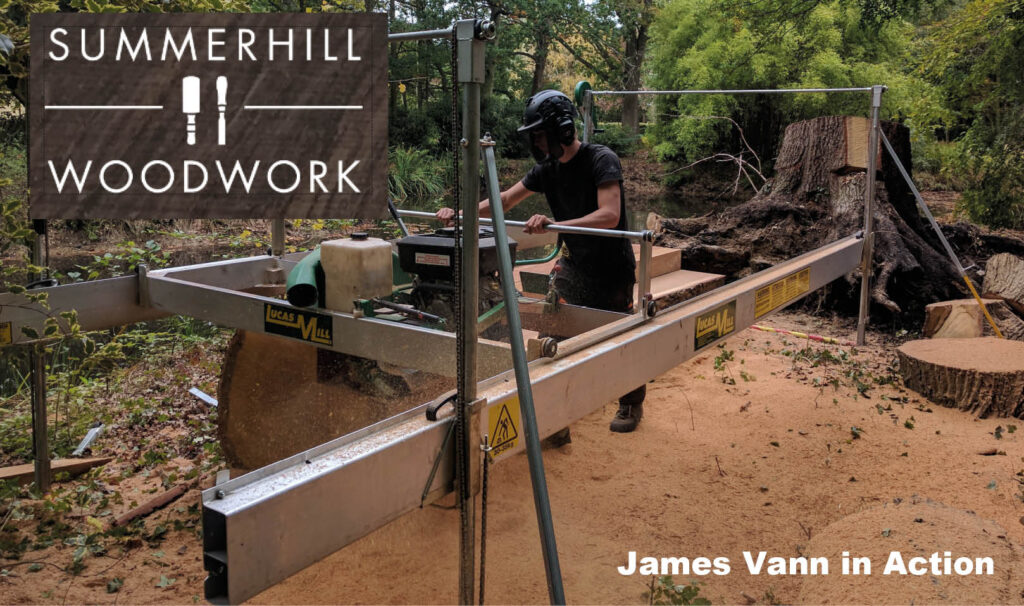

Summerhill Woodwork

Summerhill Woodwork is a relatively new business run by James Vann who is already establishing himself as a highly creative joiner and furniture maker. Located on the Kent/Essex border James works mostly in the South East. James gained his interest and knowledge of woodworking from his carpenter and joiner Dad in whose workshop James learnt his trade. James also undertook various tree work and forestry work with a friend and when just 15 would sell firewood on his Grandparent’s farm.

A turning point for James was when he saw on an ARB Forum a request from someone who wanted a table built from a tree that was felled in their garden. He got the job and made the table. The couple were so happy with it they encouraged James to have his own website and to promote himself. He now provides a variety of different saw milling and woodworking services, including joinery jobs and making furniture e.g. benches and picnic tables.

James felt he needed something to help deal with bigger timbers and after much time spent searching the Internet and watching videos, he saw the many unique benefits of the Lucas Mill in terms of its mobility, flexibility, speed and efficiency. Trees that would have taken a full day with a chain saw take much less time with a Lucas Mill. “I milled a 1.5 metre oak log in just 5 hours” says James, “No other portable saw mill could deal with that size of wood and with such speed and accuracy”.

James says he can use the Lucas Mill on his own. He sometimes asks clients to help if it’s a big job, especially where there are bigger pieces of wood as it’s quicker if there are two people. “It’s been a good investment , the Lucas Mill may seem a lot of money for what it is but it is well worth it. Although we perhaps only use it one or two days a week at the moment the time it saves and the quality of finish is exceptional” say James, “I like to see a customer’s reaction, they are impressed when I bring out the Lucas Mill to set up and they see what an efficient machine it is, rather than just using a chain saw”.

A & T Tree Specialists

Tim Worship of A & T Tree Specialists of Sutton Coldfield is a Lucas Mill enthusiast. Tim runs his two man tree surgery business much as any other tree surgeon would, but with a twist.

He has his Lucas Mill. Tim is passionate about not condemning good quality timber to firewood when it can be milled into high value product. “Location is no longer an issue” says Tim, “We have milled huge trees in locations ranging from peoples back gardens to a grave yard”. “In particular I love the idea of timber being put to good use in the same location it was felled”. Indeed Tim completed an oak framed extension to his own house on this basis and has undertaken many jobs where this has been the aim.

Tim has also invested in the slabber attachment and has been working with local joiner Joe Thompson who has been creating a variety of products from timber milled by Tim including building frames and timber buildings. “Demand for high quality timber products has never been higher” says Tim, “The Lucas Mill produces such a high quality accurate cut there is virtually no need for additional finishing work and in many cases itgoes straight from the mill onto the finished job”.

Tinne Beag Workers Co-operative Limited

Our last featured Lucas Mill users are the Tinne Beag Workers Co-operative Limited (Gaelic for A Little Fire) based on the Doon of May plantation in the South West of Scotland. Kevin Byrne is the secretary and one of the workers in the Co-operative which is not a commercial business but has 175 acres of forestry. The idea of the Co-operative is to reignite the heart of the Celtic nation and to live at one with nature in an environmental and spiritual way. They aim to live amongst the land enmeshed with what they are growing, mainly Oak, Spruce and Beech. They wish to live amongst nature and develop it for future generations. They have a community with ages ranging from 2 years old to 74 years old.

They need to have equipment to work the land and use its resources in a sustainable way. They bought a Lucas Mill in February 2017 to build their own structures. They mill the timber, have built sheds to dry out the timber and are due to build further sheds for storage. The Lucas Mill is allowing them to build numerous structures including table tops, uprights, A frame roof rafters, doors and windows.

“It’s transforming what we can do with our own timber” says Kevin. “Previously we used a chain saw and ladder as a straight edge – the Lucas Mill is a big step forward from that. The Lucas Mill is easy to use, reliable and revolutionary in terms of the size of timber we can use it with. The Lucas Mill makes it very realistic, it does right angle cuts, gets planks and beams out, ticks all the boxes, fast, efficient, accurate and safe” compliments Kevin.

They were all new to milling with five of them mainly using the Lucas Mill, although they can work it on their own when needed. Kevin feels the Lucas Mill has transformed their ability to use their timber, “The circular saw is super empowering – it has the dopamine effect. It can make something out of nothing. We cut timber down for harvesting and make into planks to the right size. Although it is not automated one person can do it and be in full control. We use the Lucas Mill every day as part of our work and will do for the foreseeable future”

Kevin said, “Fuelwood were very friendly and when they delivered the mill they showed us how to use it over two half days – we found that very useful”.

Forest Machine Magazine is written and edited by a forest professional with over 40 years hands on experience. We are dedicated to keeping you informed with all the latest news, views and reviews from our industry.

To support us you can subscribe to our bi-monthly magazine which is delivered to your door from only £30 per year.

Subscribe here

#homeoflogging #writtenbyloggersforloggers #loggingallovertheworld

-

1 Year Subscription£0.00

1 Year Subscription£0.00