Treeline Woodlands are the UK and Irish distributers for Malwa Forest Products and recently took delivery of a new Malwa forwarder.

The Malwa 560F Generation 4 is the third forwarder from Malwa that Treeline have used for their own harvesting work. The first one was purchased back in 2014 and I remember seeing it at the APF when it was just out of the wrapper. A few years later, in 2018, I had the opportunity to operate this forwarder for a few days on a first thinning near Newmains in North Lanarkshire. Overall, it was a good, nimble, and economical 5.5 tonne capacity forwarder which caused little soil disturbance, but there were a few minor bits and pieces which I thought could be improved. A few months later Treeline took delivery of a newer Generation 3 560F forwarder and again I was fortunate enough to get the chance to extract timber from a site that Nick, managing director of Treeline Woodlands, was thinning in Fife.

This forwarder was greatly improved over the previous Malwa. Upgrades included a reinforced centre joint, stronger bolsters, redesigned crane base and an 8m reach Cranab FC45 double extending loader. This was generally a much nicer Malwa to operate and the centre brake worked a lot better by offering far more stability when loading and unloading.

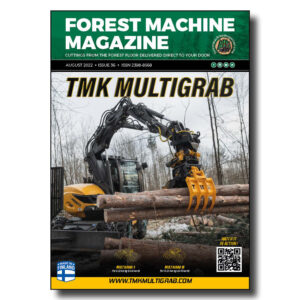

Treeline have since purchased the latest Generation 4 Malwa 560F. This machine is intended to be used on the company’s own harvesting sites as well as for hosting demonstrations for contractors looking for a low impact approach to harvesting timber.

I was looking forward to trying out the latest model and putting it through its paces. I arranged to meet Nick at a thinning site he was working outside of Haddington in East Lothian. First glance of the new forwarder revealed some obvious improvements. It looked more rugged and aggressive with the extra protection around the bonnet and side panels while still allowing access to the engine compartment for checking oils and refuelling. The side and front panels were easily removed and refitted for carrying out repairs and servicing.

Looking over the rear of the forwarder I noticed the bolsters were stronger and the crane base was perfectly engineered for the Cranab FC 45 8m reach double extending crane.

Further enhancements were not so obvious, these included a modernised control system with a larger touch screen and remote diagnostics (there is a modem for operation information directly to your smartphone). New bogie chains which are 25% stronger, and improve traction by 10%.

A smaller, powerful 2.8 ltr 75hp Caterpillar engine meets the stringent demands of Euro 5/Stage V. Both the hydrostatic drive and hydraulic pump are from Bosch Rexroth.

More illumination has been added to the cab roof and reversing lights have been added to the rear bunk of the forwarder, complementing the new bolster design.

-

That’s a remarkable amount of work hours for a single machine, the Norcar 600 owned by Erkki Rinne is taken well care of, it even has the original Diesel engine.

-

Kieran Anders is a forestry contractor working in the lake district. His work involves hand cutting and extracting timber using a skidder and tractor-trailer forwarder.

-

It is not possible to eliminate chain shot, but there are simple steps that can be taken to reduce the risk.

-

Arwel takes great pride in the fact that the mill has no waste whatsoever, “the peelings are used for children’s playgrounds, gardens and for farm animals in barns in the winter and the sawdust has multiple uses in gardens and farms as well.

-

Timber hauliers need to encourage young blood in, and also look after the hauliers we have, we need make the sector a safe and positive place to work.

FIND US ON

Nick is delighted that the engineers at Malwa listen to their customers feedback and are continually improving and updating their machines. “Apart from looks, this 4 series model and our first Malwa forwarder are worlds apart” explained Nick “everything we though which could be improved has been addressed by Malwa.”

After some instructions on which button does what I was ready to go.

The cabin is compact, which is understandable in a forwarder that is just 1.95m wide and 2.85m high but it has plenty of room to swivel the seat to stretch your arms and legs and eat your piece in comfort. The electric switch to rotate the seat instead of the older foot pedal is yet another improvement.

Vision is good, I liked the Perspex roof hatch so you could look up and see the tops of the trees, an advantage in thinnings where you can check for any hung-up overhead hazards. The control system displays all the relevant information on a single screen and is easy and straightforward to navigate.

I set off from the field where it was parked to the woodlands, the steering was quick and precise with a +/- steering angle of 45° making the forwarder easy to navigate around the standing trees. The cab and trailer track each other which makes it effortless to manoeuvre in tight crops.

Treeline were carrying out a selective thinning of the mixed hardwood and softwood trees. The timber was being cut into 3m chip which would be used for biomass. The Cranab crane was well set up and precise to use, it is surprising just how much 3m timber you could gather up in the Grippen .020 grapple. The 8m reach crane is superb for working in thinnings with the centre brake holding well. There is little movement when reaching out a with a full grapple of timber when loading/ unloading at a 90° to the machine.

Although it is a 6 wheeled forwarder it is quite comfortable when travelling. The front TRS tyres can be run at a low psi which reduces a lot of the shock you experience on larger forwarders when travelling over stumps and rough ground. For a small forwarder the ground clearance is good, with a generous 400mm and a flat underbody, so it is not liable for hanking on rougher terrain.

I thoroughly enjoyed operating the Malwa and averaged around two loads per hour. It was a reasonably short extraction distance, approximately 250-350 meters from stump to the stacking area. Just having the one spec of produce was a major advantage, there were good sized stacks in the forest where three or four forwarder stops, and you were loaded. Multiple product sizes in a thinning can be a pain for both

harvester and forwarder operators as you are picking up ones and twos of each size which can take a while to gather a load.

The Malwa has a payload of 5 tonne and weighs 5.7 tonnes so overall it is less than 11 tonnes loaded which creates little impact or soil disturbance with literally no rutting. Treeline have a 3.5 tonne payload four wheeled bolstered timber trailer that can be used on longer extraction distances or for secondary extraction over fields/narrow lanes which the 8m reach loads easily.

I looked at my fuel consumption and was averaging 4.2 litres an hour, I estimated I was carrying about 4.5 tonnes of chipwood and managing around two loads per hour. This equates to under half a litre of fuel per tonne, quite impressive when you consider the current cost of fuel and almost two days’ work between refuelling the75 ltr tank.

After a few loads I reluctantly handed the keys back to Nick, it has been a few months since I last operated a forwarder, and it was a thoroughly enjoyable experience operating this Malwa.

Looking at the machine I am amazed at the engineering progress Malwa has made over the last few years; this is a great little forwarder to operate. It is comfortable, nifty, productive and economical. Woodland owners and foresters will be delighted with how little disturbance to their forests this forwarder creates. Treeline Woodlands use it in conjunction with their small, tracked excavator-based harvester and chainsaw operators are used for any large or awkward trees.

If you would like to find out more about the Malwa thinning range of forwarder and harvesters or if you would like to arrange a demo drive of this 560F forwarder, please contact Treeline Woodlands on 01968 660698 or alternatively email them on info@treelinescotland.com.

Forest Machine Magazine is written and edited by a forest professional with over 40 years hands on experience. We are dedicated to keeping you informed with all the latest news, views and reviews from our industry.

To support us you can subscribe to our bi-monthly magazine which is delivered to your door from only £30 per year.

Subscribe here

#homeoflogging #writtenbyloggersforloggers #loggingallovertheworld

-

Issue 36£6.00

Issue 36£6.00