• Scania is introducing RB662 as a liftable and disengageable tandem bogie.

• Ideal for 6×4 or 8×4 applications such as tippers, timber trucks and other vehicles that often run unladen in one direction, reducing fuel consumption by up to 6 percent.

• Enables reduced tyre wear as well as a tighter turning radius and max load transfer for greater traction when unladen.

Scania now introduces the RB662 tandem bogie axle with an optional lift-and-disengage function. The new option, when engaged, can save up to 6 percent on fuel, depending on operation, and reduces the turning radius. Lifting takes less than 25 seconds and, with normal chassis height and tyres, ground clearance is nearly 70 mm.

“This is a highly desired function from customers in certain applications, and I’m pleased to announce this very neat solution,” says Bo Eriksson, Product Manager, Scania Trucks. “When unladen, the difference in fuel consumption can be up to 6 percent depending on the operation. That is substantial, especially when considering a return leg of 150 to 200 kilometres, as is often the case with timber trucks in Sweden. And, on top of that, you also get less tyre wear and increased manoeuvrability.”

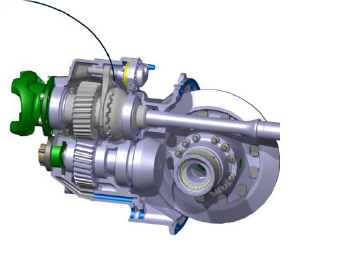

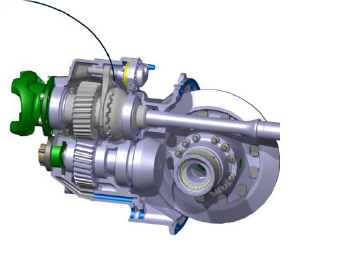

The liftable and disengageable tandem bogie (LDTA) requires air suspension and will increase the trucks kerb weight by 60 kg. Most of the fuel savings can be attributed to the reduced friction inside the second (disconnected) axle gearing and only some 10 percent of the saving derives from reduced rolling resistance. Three bogie weights – 19, 21 and 26 tonnes – are available and load limits with the second axle lifted are 9.5, 10.5 and 13 tonnes respectively.

A “dog clutch” connection is part of the option that makes Scania’s tandem axle RB662 both liftable and disengage¬able, thus offering substantial fuel savings, reduced tyre wear and much tighter turning radiuses.

The LDTA option can presently not be combined with hub reduction axles or tridem configurations. The driver raises the axle by simply turning a knob. A pop-up warning appears in the instrument cluster if the truck identifies an overload situation, in which case it will not lift the axle. The lifting can be called for at any speed. The disengage-ment itself is performed via a “dog clutch” connection.

“We definitely expect that this option will be included in many truck specifications,” says Eriksson. “The added cost will rapidly be compensated given the obvious and highly positive contribution to our customers’ total operating economy.”

Forest Machine Magazine is written and edited by a forest professional with over 40 years hands on experience. We are dedicated to keeping you informed with all the latest news, views and reviews from our industry.

To support us you can subscribe to our bi-monthly magazine which is delivered to your door from only £30 per year.

Subscribe here

#homeoflogging #writtenbyloggersforloggers #loggingallovertheworld