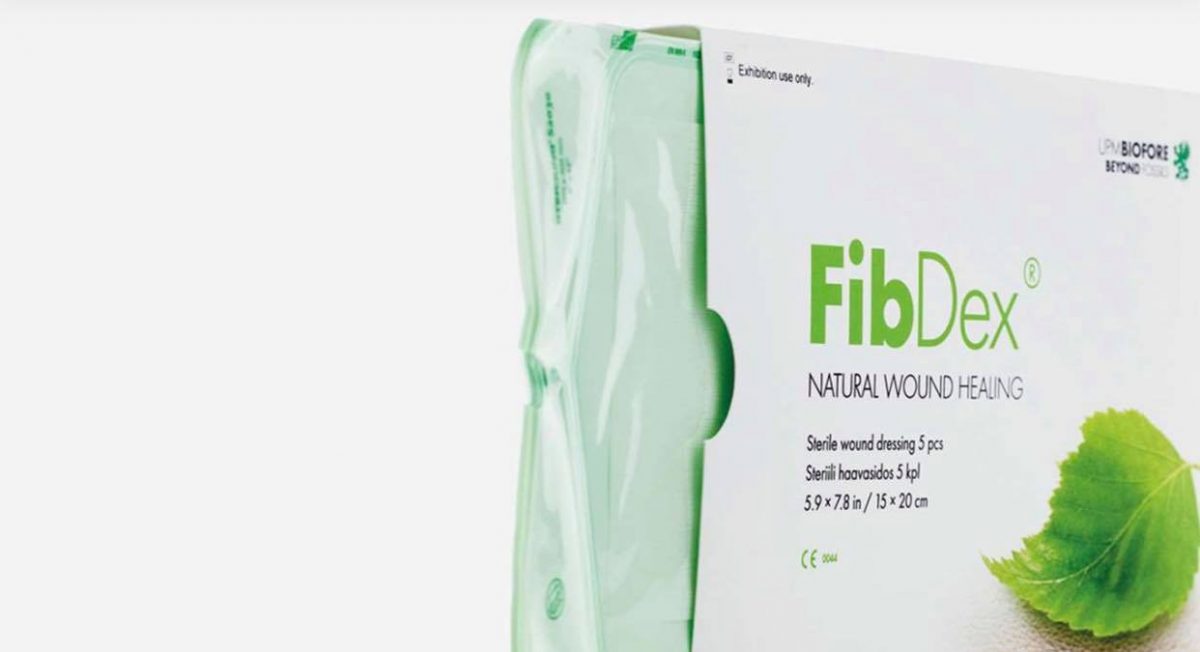

A wound dressing that can speed up healing and bring new convenience to patient care

A new wound care dressing made from a sustainable, wood-based raw material which is particularly suited to treating large wound areas.

FibDex® is a new wound care product created by UPM in collaboration with researchers from the University of Helsinki and surgeons and nursing staff from the Helsinki Burn Centre. FibDex is the third biomedical product based on renewable and responsible wood-based raw materials to be commercialised by UPM.

“Clinical trials showed the wound care dressing provides significant benefits for the treatment of skin graft donor sites”, says Johana Kuncova-Kallio, Director, UPM Biomedicals,

According to patients who took part in the clinical trial, FibDex was comfortable throughout the treatment. It was found to speed up the wound healing. It was also notable that there was a significant improvement in scar quality and vascularity.

“Changing burn patients’ wound dressings can be a very painful procedure, so both patients and nurses benefit from FibDex. It’s more comfortable for the patient and frees up nursing resources for other tasks,” adds Kuncova-Kallio.

A biomedical innovation

The innovation was conceived when Marjo Yliperttula, Professor of Biopharmaceutics at the University of Helsinki, developed an interest in nanofibrillar cellulose. Yliperttula and her research team proved that nanofibrillar cellulose could be used for cell culture and wound care as well as various other applications.

“Skin grafts are used to treat severe burns, skin cancer and plastic surgeries. Skin is removed from the patient’s back, for example, and transplanted onto the part of the body needing treatment,” she explains.

Skin graft donor sites are very painful and can be difficult to heal. The donor site must be dressed, but as the skin heals and grows, the new skin can stick to the dressing when the dressing is changed.

”This is not happening with FibDex as the dressing is only applied once at the start of treatment. During the healing process FibDex gradually detaches itself from the donor site once the skin beneath has healed. The dressing, made from nanofibrillar cellulose, provides a moist environment for optimal healing and absorbs fluids from the wound. Just one dressing is required throughout the whole treatment,” notes Yliperttula.

Nanocellulose has surprised the researchers time and time again. Several new treatments are being studied, promising faster healing and discharge of patients.

“We can place medicines, antibacterial agents, and even stem cells into the nanocellulose membrane. The fact that nanocellulose appears to apply to freeze-drying of biological materials for biobanks also offers significant growth prospects,” Yliperttula added.

Innovating for a future beyond fossils

Market entry in Finland

As UPM’s products are newcomers to the biomedical and clinical applications markets, it will take a lot of work to increase recognition of both the company and its products.

In Finland, FibDex® wound dressing has taken a significant step in its path to market, as leading medical device distributor Steripolar Oy now sells the product.

Kaj Dahlström, CEO of Steripolar says that Fibdex is a new and very interesting Finnish innovation that fulfils the criteria of sustainable development.

“We want to provide products and solutions that offer pain-free healing of patients. We also require that the operations of our partners are sustainable. We are glad to offer solutions that allow us to support our customers’ environmental thinking.”

FibDex was granted the CE-marking in May 2019. This approval was a significant milestone, allowing the marketing and sale of the wound dressing in the EU. Registration with the US Food and Drug Administration (FDA) is also pending and will open the doors to US markets in due time.

“We are aiming for global markets. In addition to Europe, the product can be sold in countries outside of the European Union which accept the European CE mark. The United States and China have different regulatory requirements,” says Kuncova-Kallio.

“Thanks to GrowDex® hydrogel for 3D cell culture, we have learnt how wood-based materials can benefit our customers, researchers and patients. We used this knowledge and expertise to our advantage when developing FibDex.”

Text: Vesa Puoskari

Forest Machine Magazine is written and edited by a forest professional with over 40 years hands on experience. We are dedicated to keeping you informed with all the latest news, views and reviews from our industry.

To support us you can subscribe to our bi-monthly magazine which is delivered to your door from only £30 per year.

Subscribe here

#homeoflogging #writtenbyloggersforloggers #loggingallovertheworld