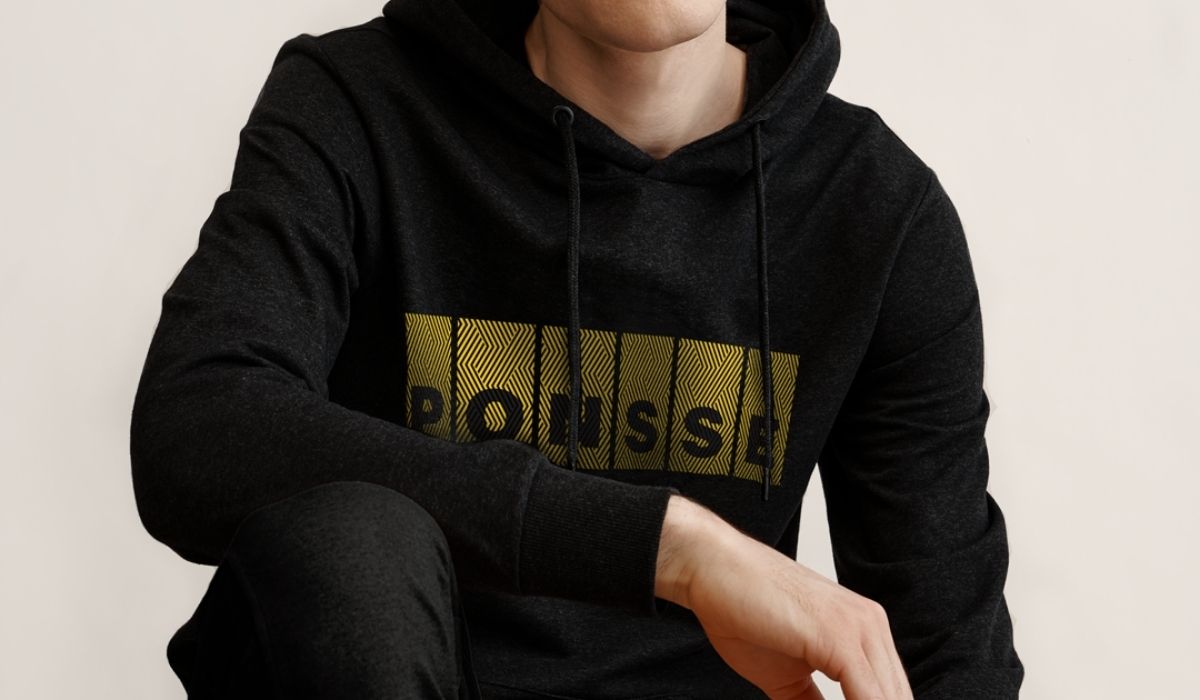

Ponsse Plc has started a sustainable brand product partnership with Globe Hope. The partnership started with business apparel made from recycled yarn.

Ponsse Plc started cooperating with Globe Hope in 2021 to make its brand products more sustainable. The first step in the partnership was taken with business apparel made 100% from recycled materials and branded with Ponsse’s well-known logo.

Globe Hope’s business apparel are made from innovative recycled yarn, which consists of the textile industry’s cotton waste and recycled plastic bottles. A single hoodie made from recycled materials saves 3,812 litres of water and 2.2 kg of carbon dioxide emissions.

Both partners have been satisfied with their cooperation, and the development of the sustainable Ponsse Collection will continue.

“Our partnerhsip with Globe Hope has been productive, and we have learned a lot about sustainable textile production. Our cooperation will also continue in the future, as Ponsse’s goal is to develop constantly to become an even more sustainable company in everything we do. Ponsse’s employees and customers have given this partnership a warm welcome, and many were already familiar with Globe Hope as a brand,” says Laura Kouvalainen, marketing specialist responsible for Ponsse’s branded products.

“We are proud of this new partnership. Companies’ actions and choices play a significant part in combating climate change. It’s great to see how significant sustainability is in Ponsse’s operations. Correctly selected brand products are also essential in how companies communicate their sustainability. We hope that our partnership leads the way for other companies as well,” says Seija Lukkala, founder of Globe Hope.

Globe Hope’s PONSSE hoodies and sweatpants are now available for sale in Ponsse’s online shop and at service centres. Check Globe Hope’s PONSSE products and other Ponsse Collection products in the online shop.

-

That’s a remarkable amount of work hours for a single machine, the Norcar 600 owned by Erkki Rinne is taken well care of, it even has the original Diesel engine.

-

Kieran Anders is a forestry contractor working in the lake district. His work involves hand cutting and extracting timber using a skidder and tractor-trailer forwarder.

-

It is not possible to eliminate chain shot, but there are simple steps that can be taken to reduce the risk.

-

Arwel takes great pride in the fact that the mill has no waste whatsoever, “the peelings are used for children’s playgrounds, gardens and for farm animals in barns in the winter and the sawdust has multiple uses in gardens and farms as well.

-

Timber hauliers need to encourage young blood in, and also look after the hauliers we have, we need make the sector a safe and positive place to work.

Find Us On

Forest Machine Magazine is written and edited by a forest professional with over 40 years hands on experience. We are dedicated to keeping you informed with all the latest news, views and reviews from our industry.

To support us you can subscribe to our bi-monthly magazine which is delivered to your door from only £30 per year.

Subscribe here

#homeoflogging #writtenbyloggersforloggers #loggingallovertheworld

-

1 Year Subscription£0.00

1 Year Subscription£0.00 -

2 Year Subscription£0.00

2 Year Subscription£0.00 -

Issue 32£6.00

Issue 32£6.00 -

Embroidered Beechfield Beanie£9.95

Embroidered Beechfield Beanie£9.95 -

Sustainable Logging: Powering The Planet T-Shirt£17.50 – £20.00

Sustainable Logging: Powering The Planet T-Shirt£17.50 – £20.00 -

Sustainable Logging: Powering The Planet Hoodie£33.00 – £36.00

Sustainable Logging: Powering The Planet Hoodie£33.00 – £36.00