Steep Slope Logging

Skylines were the pioneering equipment for steep slope logging, the first documented appearance dates back to 1886. Radio control in the 1960’s, grapple carriages in the 1970’s and automated carriages in the 1980’s/90’s, have all helped to improve efficiency and increase production, but they are still labour intensive and an expensive system for extracting timber.

The first Traction Assist Winch I saw working was at the Austrofoma show in 2015. The Austrian event focuses on steep logging conditions with regards to soil conserving timber harvesting.

It was a wet miserable September and I remember being amazed at the John Deere 1110 forwarder, which was on tyres, reversing and loading up a wet greasy sloped field while attached to a T Winch. There was barely a mark on the ground where it was traversing. I know from experience a forwarder would have needed two sets of band tracks, and the whole area would have looked like a ploughed field.

This event was an eye opener as there was a host of Traction Assist Winches to view, including an integrated chassis winch on a HSM 208F Forwarder, and a selection of machine mounted and remote-controlled tractor mounted winches, from the steep logging specialist, HAAS Maschinenbau.

I have always been uneasy about the thought of dangling off the edge of a very steep slope, with only a winch cable, saving me from setting a new forwarder land speed record. But since 2019 I have visited a few harvesting sites in the UK where traction assist winches were being utilized and can confirm my fears have been put to rest.

Winch-assist systems have seen rapid development, adoption, and implementation in many parts of the world in the past decade and can be considered one of the major recent innovations in steep terrain harvesting. Though a comparatively young topic, the literature surrounding them has grown considerably.

Worker’s safety has increased through winch-assist systems by removing workers from the many hazards of manual and motor-manual work. The extent of rutting, subsequent erosion, and soil densification after working with winch-assist systems is found to be similar to operations on gentle terrain or cable logging and is considered more productive than conventional steep terrain harvesting.

-

That’s a remarkable amount of work hours for a single machine, the Norcar 600 owned by Erkki Rinne is taken well care of, it even has the original Diesel engine.

-

Kieran Anders is a forestry contractor working in the lake district. His work involves hand cutting and extracting timber using a skidder and tractor-trailer forwarder.

-

It is not possible to eliminate chain shot, but there are simple steps that can be taken to reduce the risk.

-

Arwel takes great pride in the fact that the mill has no waste whatsoever, “the peelings are used for children’s playgrounds, gardens and for farm animals in barns in the winter and the sawdust has multiple uses in gardens and farms as well.

-

Timber hauliers need to encourage young blood in, and also look after the hauliers we have, we need make the sector a safe and positive place to work.

FIND US ON

Related Posts

I have recently seen two very different techniques which are both safe and very effective methods of working on steep ground. One is the Timber Max Traction Assist Winch and the other is a Menzi Muck.

Timber Max Traction Assist Winch

RJ Fukes Forestry Services are the UK and Ireland distributers for Timber Max products. The family run company offer a hire service on the T10 winch at realistic prices so steep areas can be factored into contracts without breaking the bank.

The T10 winch is excavator mounted and can work on distances up top 480m, it has an 11-tonne constant pull, with a speed of up to 5.5 feet per second. The hirer pays transport costs, and the minimum hire period is two weeks. The hire includes operator training on the safe use of the equipment, and it takes just 40 minutes to add displays and set up the slope machines ready for work. Swapping the winch from one machine to another takes just 30 minutes.

The Timber Max winches are compact and feature a built-in spooling device. The ability to mount the winch directly on to a skidder, harvester, forwarder or an excavator makes the system an attractive and cost-effective option.

I have recently visited three separate sites where a Timber Max winch has been used.

Dick Brothers Forestry Ltd

My first visit was to the A7 near the Moss Paul Hotel in the Scottish Borders. The harvesting had been completed but a brash recovery operation was underway.

Operating a Komatsu 875 Forwarder for the Dick Brothers Forestry Ltd was Gary Humphries. The Komatsu was attached to a Timber Max T10 mounted on the rear frame and fed over the boom of a Volvo excavator via a series of pulleys. This setup lends itself well as a multiuse system as the slope machine can be easily detached and used as a normal excavator.

Gary was travelling down the steep hill, headfirst, on the bare ground between the brash mats. The photo shows that the soil structure is completely undisturbed by the harvesting, extraction and brash recovery operations. The Timber Max certainly inspired confidence on the steep hillside as Gary felt completely secure when loading and travelling. The T10 has a constant pull of 10 tonnes and the 16mm cable has a breaking strain of 24 tonnes.

The display is mounted to the tethered machine, and relays essential information to the operator via a high-contrast, 12“monitor. Additional information includes diagnostics, troubleshooting, and statistics.

This was the perfect site to show the advantages of the Timber Max traction assist winch as the whole hillside is clearly visible from the busy main road. Now the work is completed, there is barely a mark on the hillside where the machines have been working.

Elliot Henderson Group

In the Ettrick Valley was another steep site that was being clear-felled by the Elliot Henderson Group.

Again, the Traction Aid Winch was a Timber Max T10, but this time it was mounted on a Case 220 Excavator and extracted with a John Deere 1910G forwarder. The 1910G, with the rotating levelling cabin, lends itself well to steep slope logging as there is less stress on the cabin with the 9° forward/rear tilt angle.

The Komatsu 931XC harvester had used another T10 winch which was mounted on a Doosan T100. Both winches were mounted onto the dipper boom where the digging bucket would normally be.

Each drift was in excess of 300m, and the winch was situated at the top of the hill with the forwarder reversing up empty and loading on the way down. The iWinch® system recognizes which direction the slope machine is moving. It can be set to 3 different tension settings: Uphill, Not Moving and Downhill and the operator can reduce the pre-set tension with the potentiometer.

It was a very steep click off the road initially and then a constant pull of 30-35% to the top of the hill. The forwarder was extracting to the road at the bottom of each drift and a Ponsse Buffalo carried out a secondary extraction to a stacking point a few hundred meters down the road. Again, this system worked well with little evidence of any soil disturbance on the hill.

The forwarder had an extra headboard slotted between the bunks, so that when loading two separate bunks, the load is kept tidy and secure. The mid mounted headboard is easily moved with the crane and can be mounted behind the rear bunk for uphill extraction. I spent around five hours watching the forwarder on the hill and was mightily impressed with the speed of production and effectiveness of the winch.

The slow constant winch pull, which matched the forwarders transmission speed, prevented any wheelspin or slipping on the brash mat. This is much easier on the equipment as diff locks are rarely required and it isn’t necessary to slew from side to side on the steering to get grip.

John Smith

My final visit was to another steep site in Dumfries and Galloway to see a pair of T10 winches which were on hire to forestry contractor John Smith.

John decided to hire the Timber Max winches from R J Fukes Forestry Services for a few months as it was a more affordable and quicker option than a traditional skyline.

This was another steep uphill extraction which had been harvested with a Komatsu 951 harvester and extracted to the top of each drift with a Komatsu 855 forwarder. A 1510G John Deere forwarder carried out a secondary extraction from the top of the drift to the stacking area.

The 855 had an extra rear mounted headboard to prevent the timber sliding off the back, personally I think uphill extraction is much easier on the kingpost as the crane is slewing uphill empty and downhill full.

The drifts were around 100m in length, but the slope was 35°, which would have been almost impossible to forward without a winch. The only other option would have been to hand fell the timber and extract it with a skyline, which would have been very costly.

John was delighted with how the Timber Max winches had performed. My visited came after a prolonged spell of heavy rain and the ground was sodden. From what I could see there was no water issues as the brash mats remained relatively undisturbed.

The Timber max is an excellent solution which not only protects the soil structure but keeps operators secure on steep ground and prolongs the life of equipment by reducing wear and tear. For more information on the Timber Max or hiring costs please contact John at

admin@rjfukes.co.uk

www.timbermax.ca

A visit to Northumberland generated a totally different approach for steep ground harvesting.

Metsa Ltd

Metsa were established just over three years ago. From their head office in Edinburgh they provide specialist plant services to the forestry and civil engineering sectors.

The company’s primary focus is operations in challenging locations and sensitive environments. They have worked with a wide range of clients from private landowners, community forests charities, and large national and multinational contractors. Metsa’s senior leadership team comprises a mix of ex-military and civilian operatives all of whom bring extensive experience in their field. The teams need to be able to problem solve and adapt quickly to meet operational, environmental and clients’ changing needs when operating in challenging locations or conducting complex tasking.

It was a chance meeting at a forestry function with Alan Brown, Operations Director at Metsa Ltd, that got the ball rolling. From this, I met Dave Godfrey, one of the company directors, at a site they were working near Otterburn in Northumberland, and he explained about the companies aims.

“We are committed to providing first class equipment, training and renumeration to our employees engendering retention through a sense of ownership and personal control. Being a veteran led organisation we are committed to providing opportunities for ex service personnel and actively recruit and train people from this background. All of our machines are forestry specification and come operated by a fully certified and qualified operator; with our operators having extensive experience working and operating machinery in remote locations across Scotland. All hold the relevant CITB CSCS qualifications and cards and are fully first aid trained.”

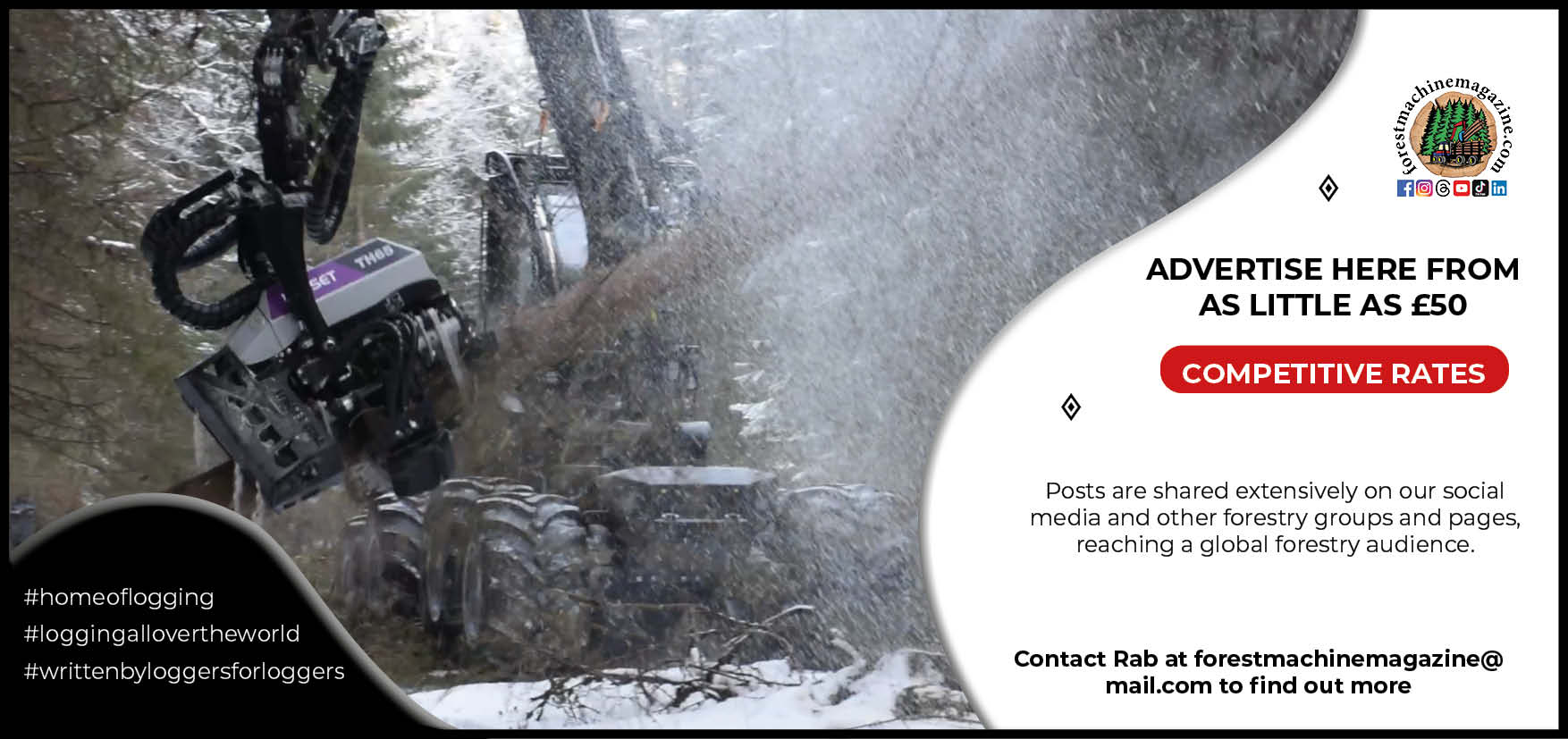

This clear fell was being harvested by operator Jamie Wright with a Menzi Muck M545X. The Menzi was fitted with a Hultdins saw on a Powerhand grapple and working for Colin Robertson, Walton Logging Ltd, the main contractor.

The Valley was incredibly steep with a fast-flowing stream running along the bottom of the felling area and was being harvested from top to bottom. Dave explained that the Menzi was capable of safely working on slopes in excess of 45° and that it is perfect for this type of work. The four independently adjustable legs mean that the operator and engine are always sat level no matter what the slope.

The walking excavator is a clever piece of equipment and is not overly heavy at 13.5 tonnes. It has a mighty 4.5 tonne lift on the crane at 8m reach. Every possible extra has been fitted so that it is of the highest specification possible. A traction assist winch is also installed, which gives the operator added security when felling on the steepest areas. The panoramic cab gives an unobstructed view of the entire site and machine chassis for safety, ergonomics and fatigue-free working.

Jamie made short work of felling and stacking the trees into drifts. He has over 5,000 hours experience on the Menzi and can work it to its full potential. The 360° high volume Steelwrist that is fitted between the grapple and dipper made it look easy manoeuvring the felled trees into position. All the butts were exposed and lined out one way so that the skyline could extract them to the top of the hill. Jamie has been achieving around 200m³ per day, but this is dependant on the ground conditions and tree size.

Once at the top, the trees were then processed by a Tigercat harvester before being forwarded down a diagonal track, which was excavated across the hill, to the stacking area at the bottom. The track on the hillside is to be reinstated once harvesting is completed.

This was one of the steepest harvesting sites I had ever seen. It would have been incredibly difficult for chainsaw operators to work without losing their footing, and with a high percentage of windblown timber it would have been extremely hazardous and impossible to lay out all the trees in one direction.

Dave uses his extensive military training so that every job carried out has been planned down to the finest detail. They are a tech orientated company and use drones equipped with Lidar to create a 3D representation of the ground they will be working and work along with Glasgow University.

Three years is the maximum time that Metsa will keep the Menzi Muck working in these conditions as they are committed to offering their clients a professional and prompt service using the best equipment available.

Although Metsa is a relatively young company their equipment inventory is impressive.

- Menzi Muck M545X – a 14.5T walking and climbing all-wheel drive excavator, capable of accessing difficult terrain and slope up to 45+ degrees un-winched with minimal impact, runs a wide range of high-capacity attachments.

- Menzi Master M515 – 14.5t a low ground pressure tracked excavator capable of safely operating on slopes up to 40 degrees and able to a run wide range of high-capacity attachments.

- Menzi Muck M340 – A 11t walking and climbing all-wheel drive excavator, capable of accessing difficult terrain with minimal impact.

- Komatsu 855 Forwarder. Medium weight forwarder capable of forwarding 15t complete with band tracks.

- Takeuchi TB290-2 – 9T low ground pressure excavator available with widespread tracks for soft and peat related work.

- Takeuchi TB260 – 6T 360 excavator, fitted with forestry grab, winch and tree shear. Perfect for first thinnings, general forestry ground works

- Tracked Forwarder – 6T Tracked forwarder capable of being winched, and extraction of timber from difficult of sensitive locations.

Attachments:

- 400mm tree sheer

- 600mm Grapple Saw and Powerhand Grab

- 600mm Harvesting head

- Monteberg Rock Breaker

Dave was also keen to point out the type of work they undertake. “We have invested heavily in specialist equipment, to enable us to undertake works in environments where standard equipment would not necessarily cope reliably. More importantly the operators of our equipment are subject matter experts on that kit and understand the importance of imbedding and becoming part of a project team. In essence, Metsa exists to deliver solutions where the route to ultimate success is not necessarily clear. Operating safely in a highly regulated environment, whilst still maintaining the ability to think laterally and adapt in highly challenging situations is where we aim to provide value to our clients. We offer the following services”.

- Forestry ground preparation, access construction and environmental engineering. For example, we have supported the woodland creation schemes for three large estates on the Isle of Mull where we have mounded c230ha, built 15km of access paths, ATV tracks and roads.

- Civil groundworks, with a focus on steep, remote and difficult terrain. For example, we have supported McGowan Environmental Engineering and SSE to install an 11KV cable to the Ptarmingan Station on Cairngorm Mountain.

- Woodland thinning and maintenance services as part of a wider management plan. Working with NatureScot we have recently won a tender to manage invasive scrub on a number of SSSI sites across the central belt.

- Tree felling and removal services, for example Ash die back management projects. We have conducted an extensive programme of thinning and Ash removal works for Hopetoun House Estate and Belsyde Farm and are working with a number of landowners to manage the impact of windblown trees following severe weather in 21/22.

- UAS Ground Penetrating Radar, Photogrammetry and LIDAR Surveys, and associated GIS workflows. Each or project is directly supported by our own in-house survey team enabling operator to remotely plan and rehearse complex project evolutions.

- Steep Ground Harvesting and Forwarding. Our machines are capable or steep ground felling and preparation for extraction eliminating the traditional need for hand fellers on terrain a standard harvester cannot operate.

www.metsaltd.co.uk

Forest Machine Magazine is written and edited by a forest professional with over 40 years hands on experience. We are dedicated to keeping you informed with all the latest news, views and reviews from our industry.

To support us you can subscribe to our bi-monthly magazine which is delivered to your door from only £15 per year.

Subscribe here

#homeoflogging #writtenbyloggersforloggers #loggingallovertheworld