Richard Newton, forestry lead for CRJ Services, explains how chipper maintenance is essential to producing wood chips that meet customer requirements. However, it also reduces fuel consumption, makes the most of operators’ time and ensures a long life for high-value machines.

Most wood chips in the UK are produced for biomass energy production in thermal power stations or combined heat and power (CHP) units. A challenge with chipping is that it is a tough job in a harsh environment. Components in machines can experience excessive wear, especially when logs, brash or roots have become

contaminated with sand or mud. Even though wood is a lot softer than the steel components inside chippers, the large throughput of material will eventually wear the steel away.

Most customers in the UK need chips in the G30, G50 or G100 grades, with larger generators requiring larger sized chips. However, other grades also exist – for example, there was a trend for very small micro-chips, while other chips are used in horticulture. The size of the chips is important for efficient burning and power production. It’s also important for handling that chips have a consistent shape. If they are too large, they could bridge across a duct and block it, whereas wood dust and fines can choke up pipework. A lot of chipping operations are carried out at remote sites in the field, so chippers often need to be mobile machines that have their own diesel engine.

Beyond that, successful chipping often depends on site-specific factors, such as the conditions on site, the type of soil and whether it has contaminated the wood or brash to be chipped, accessibility and whether the material to be chipped is a neat stack of logs or a tangled pile of tops and branches. Availability of trucks to transport chipped material in a timely manner is also important to avoid the chipper and its operator sitting idle while they wait for a truck.

How wear affects operations

There are two basic types of chipper. At the smaller end of the market, machines are based on a single disc that spins to break up material. When it comes to medium and large industrial chippers, these have working parts based on a rotating cylinder with knives mounted into it. The knives catch material fed into it at right angles and cut it into chips against a static counter-knife.

In general, the smaller the chip size, the faster the wear on a chipper and the higher the fuel consumption. That is because it takes more energy to break wood and brash into smaller chips. In addition, components can experience damage if foreign objects find their way into the machine.

Once components experience wear, knives lose their sharpness and clearance distances become larger. This makes the resulting chips larger in size. As a result, operators may need to pass chips through a machine more than once. Not only does this take longer but it also burns additional fuel.

Operators can prevent this by performing maintenance when they see excessive wear building up on critical components.

-

That’s a remarkable amount of work hours for a single machine, the Norcar 600 owned by Erkki Rinne is taken well care of, it even has the original Diesel engine.

-

Kieran Anders is a forestry contractor working in the lake district. His work involves hand cutting and extracting timber using a skidder and tractor-trailer forwarder.

-

It is not possible to eliminate chain shot, but there are simple steps that can be taken to reduce the risk.

-

Arwel takes great pride in the fact that the mill has no waste whatsoever, “the peelings are used for children’s playgrounds, gardens and for farm animals in barns in the winter and the sawdust has multiple uses in gardens and farms as well.

-

Timber hauliers need to encourage young blood in, and also look after the hauliers we have, we need make the sector a safe and positive place to work.

FIND US ON

Related Posts

Keeping knives sharp

Knife inspection and sharpening is one of the most important maintenance tasks on a chipper. Operators should carry out a visual inspection of the knives on the rotor and the leading edge of the counter-knife at least once or twice every day.

It’s fairly straightforward to open up the machine in the field and sharpen the rotor knives with an angle grinder or replace them with spares. Typically, counter-knives need to be changed every 200-300 hours.

The operator should also take care to maintain a good clearance distance of 0.2 – 0.5 mm between the rotor and counter-knife, which will increase as a result of wear or sharpening. Some chippers are designed with this in mind as they come with a set of shims that the operator can fit underneath the knives on the cylinder to maintain the overall diameter.

Impact of wear on accessories

It’s not just the chipping mechanism itself that experiences wear. Components such as chutes and blower hoods can be worn away by abrasion from fast-moving wood chips and airborne fines. Excessive wear of these types of chip handling equipment will also have a big impact on productivity as they ensure chips are fed into trucks and are not spilled onto the ground, where they can get dirty or lost.

Welding on a hardened steel wearplate of a hardfacing coating can prevent this. These are made from hardened steel rather than a more general-use carbon steel. The hardened steel is formulated to be tougher and more resilient to impact and abrasion, and in turn this enables these component to provide a service life of 2,000 hours or more.

Another area where hardened steel can be helpful is around the edges of the rotor. Foreign material can find it’s way into the sides of a rotor, where it presses into the cylinder and wears away the steel that supports the knives. This can be avoided by adding sacrificial wearblocks at the edges of the rotor. These are much quicker to replace than the cylinder itself and can be reversed or replaced when their outer surface becomes worn.

Machines designed for high availability

When specifying a large mobile chipper, every operator has preferences in terms of the type of rotors, tyres, cranes and grabs. In addition, they might prefer a chipper that is truck-mounted, trailer-mounted or tractor-driven.

Other features can also help to ensure high availability of a machine in the field. For example, some chippers have been designed with systems that slow down the infeed of material when sensors detect that the counter-knife has experienced excessive force, impact or vibration.

Similarly, it’s possible to get chippers that will stop feeding material in when the rotor RPM slows down when needs to handle an excessive quantity of material or particularly hard or tough material. This prevents the likelihood of a chipper stalling during operation so that it can recover and keep operating throughout the shift.

Lifetime of 20 years

The high cost of diesel has made it more important than ever to control the cost of operations in the field and keep machines running for longer. With good maintenance in the field and main servicing after every 250 hours of operation, operators can minimise power consumption, ensure high-quality chips are produced and extend the service life and availability of equipment.

As a service contractor, we provide support to sites anywhere in the UK, as well as scheduled main servicing and spares. We see all sorts of equipment and provide support to machines that are still operating successfully after a life of more than 20 years.

www.crjservices.co.uk

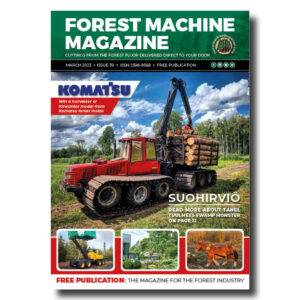

Forest Machine Magazine is written and edited by a forest professional with over 40 years hands on experience. We are dedicated to keeping you informed with all the latest news, views and reviews from our industry.

To support us you can subscribe to our bi-monthly magazine which is delivered to your door from only £15 per year.

Subscribe here

#homeoflogging #writtenbyloggersforloggers #loggingallovertheworld

-

1 Year Subscription£0.00

1 Year Subscription£0.00 -

2 Year Subscription£0.00

2 Year Subscription£0.00 -

Issue 40£0.00

Issue 40£0.00 -

Issue 39£0.00

Issue 39£0.00 -

Sustainable Logging: Powering The Planet T-Shirt£17.50 – £20.00

Sustainable Logging: Powering The Planet T-Shirt£17.50 – £20.00 -

Sustainable Logging: Powering The Planet Hoodie£33.00 – £36.00

Sustainable Logging: Powering The Planet Hoodie£33.00 – £36.00