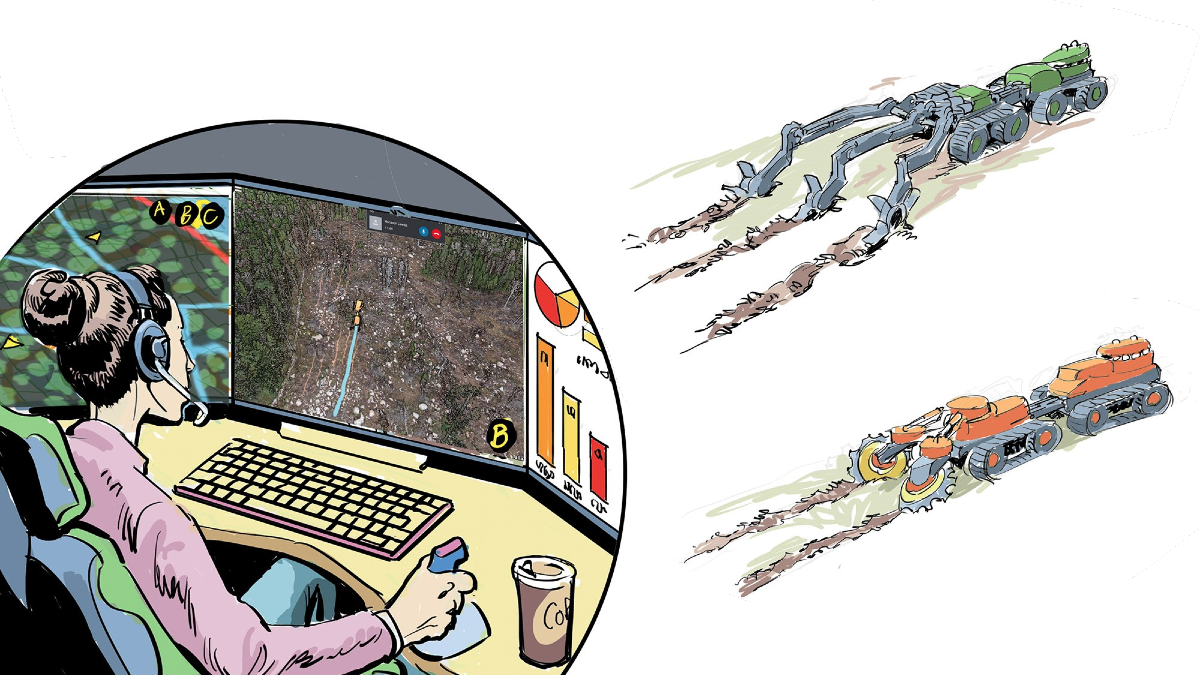

The Forestry Research Institute of Sweden (Skogforsk) has started the development of a remote-controlled soil preparation machine. This takes place at Troëdsson Forestry Teleoperation Lab in Jälla, just outside Uppsala.

For several years, the Forestry Research Institute of Sweden (Skogforsk) has worked with remote control and automation of forest machines at the technology lab in Jälla. So far, the work has been concentrated on one forwarder, but now a soil preparation machine has also arrived in the test environment. The goal is to bring the technology for the remote-controlled of forest machines closer to application,” says Martin Englund, technical specialist at the Forestry Research Institute of Sweden, and responsible for the project.

“We believe that scarification machines are less complicated to control remotely than forwarders and harvesters. Scarifiers move over clearcuts where most of the trees are gone, which facilitates communication between the machine and the operator station. By developing and testing remote-controlled soil preparation, we will find out what additional knowledge and technology is needed for remote control of machines to work in forestry in general,” he says.

The work environment is an important reason

Another reason why scarifiers are interesting for remote-controlled is that operators of these machines are exposed to harmful whole-body vibrations to a greater extent than other machine operators in forestry. The vibrations could be avoided if the machines were instead operated remotely in a stand-alone operator station.

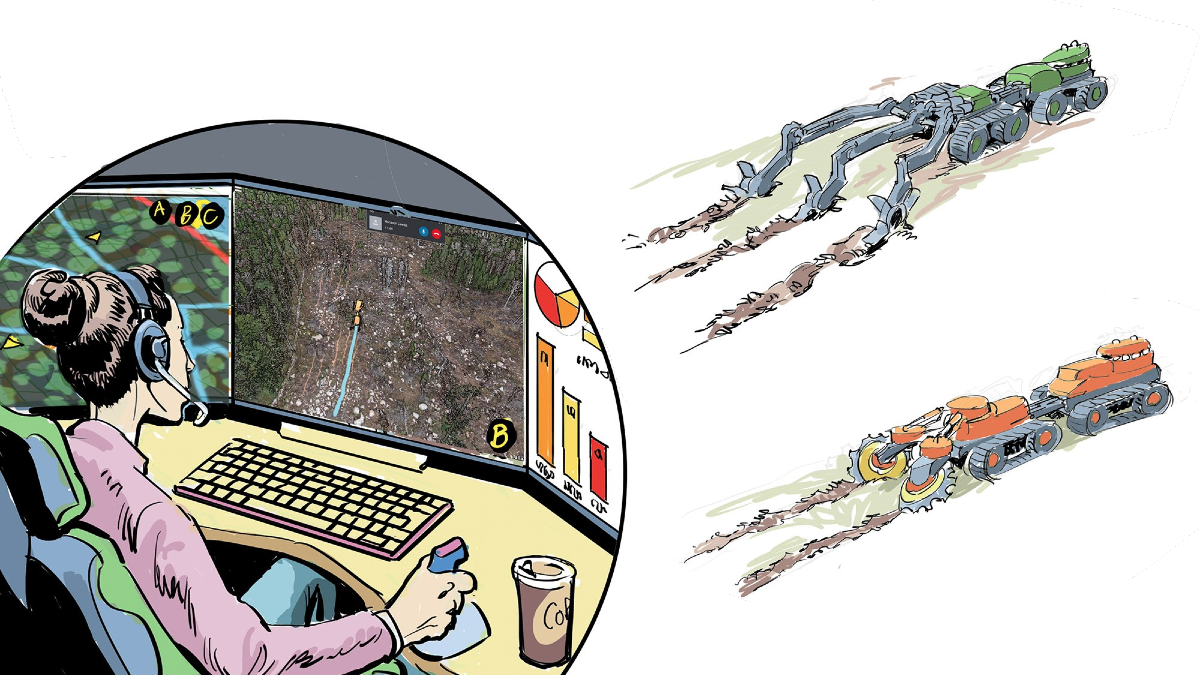

The forest machines of the future can be remote-controlled, and soil preparation machines are the most suitable to start with, according to the Forestry Research Institute of Sweden. Illustration: Gösta Lindvall

-

That’s a remarkable amount of work hours for a single machine, the Norcar 600 owned by Erkki Rinne is taken well care of, it even has the original Diesel engine.

-

Kieran Anders is a forestry contractor working in the lake district. His work involves hand cutting and extracting timber using a skidder and tractor-trailer forwarder.

-

It is not possible to eliminate chain shot, but there are simple steps that can be taken to reduce the risk.

-

Arwel takes great pride in the fact that the mill has no waste whatsoever, “the peelings are used for children’s playgrounds, gardens and for farm animals in barns in the winter and the sawdust has multiple uses in gardens and farms as well.

-

Timber hauliers need to encourage young blood in, and also look after the hauliers we have, we need make the sector a safe and positive place to work.

FIND US ON

Related Posts

“That should mean big improvements in the working environment. In the long run, it should also mean that the driver’s cab, with its associated advanced systems, should be able to be rationalized away. This would result in both cheaper and lighter machines,” says Martin Englund.

The remote-controlled scarification machine will be developed gradually during the spring and will be tested in an ordinary clearcut after the summer. It will then be controlled by drivers from an operator station near the clearcut. Through interviews with the drivers, areas of knowledge and development that need to be strengthened will be identified. Furthermore, the plan is to demonstrate the machine to stakeholders and the media during the autumn.

Current status of the project:

- Tests with remote control of a full-scale soil preparation machine are underway at the technology lab in Jälla.

- Remote-controlled driver environments are being tested in the real-time simulator Troëdsson Forestry Technology Lab at the Forestry Research Institute of Sweden in Uppsala.

- In mid-April, operator environments will be tested in the real-time simulator by professional operators of scarification machines.

The project is funded by the Nils & Dorthi Troedsson Foundation Research Fund. SCA Skog will contribute with the base machine and Bräcke Forest with the scarification unit.

Forest Machine Magazine is written and edited by a forest professional with over 40 years hands on experience. We are dedicated to keeping you informed with all the latest news, views and reviews from our industry.

To support us you can subscribe to our bi-monthly magazine which is delivered to your door from only £15 per year.

Subscribe here

#homeoflogging #writtenbyloggersforloggers #loggingallovertheworld