Everything we do at John Deere is focused on real purpose and real impact. This means we’re developing technology like ExactShot that enables our customers to provide the food, fuel, fiber, and infrastructure that our growing global population needs.” Jahmy Hindman

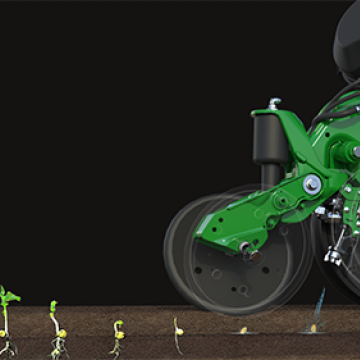

EXACTSHOT

ExactShot enables farmers to reduce the amount of starter fertilizer needed during planting by more than 60%, notes Deanna Kovar, vice president, production & precision ag systems at John Deere. Rather than apply a continuous flow of fertilizer to the entire row, the technology uses sensors and robotics to place starter fertilizer precisely onto seeds as they are planted in the soil. Using a sensor to identify when each seed is planted, ExactShot then applies only the amount of fertilizer needed, about 0.2 ML, directly on the seed as it goes into the ground.

Kovar says that across the U.S. corn crop, ExactShot could save over 93 million gallons of starter fertilizer annually and prevent wasted fertilizer from encouraging weed growth or increasing the risk of running off the field into a waterway.

- READ MORE: John Deere wins two CES innovation awards

FULLY ELECTRIC EXCAVATOR

Powered by a Kreisel battery, the fully electric excavator will lower daily operating costs, reduce noise pollution, improve machine reliability, and offer zero emissions without sacrificing power and performance. Deere acquired majority ownership of Kreisel in early 2022, which has a facility in Austria. In September 2022, Deere announced an investment in two additional Kreisel Electric production facilities to increase battery production capacity. This expansion will bring an increase of over two Gigawatt hours to Deere’s total battery production.

Kreisel’s patented immersion cooling architecture provides lifetime, enhanced safety, and improved performance for battery-powered equipment. The company’s charging technology enables faster, lower-cost connections to the electrical grid.

-

That’s a remarkable amount of work hours for a single machine, the Norcar 600 owned by Erkki Rinne is taken well care of, it even has the original Diesel engine.

-

Kieran Anders is a forestry contractor working in the lake district. His work involves hand cutting and extracting timber using a skidder and tractor-trailer forwarder.

-

It is not possible to eliminate chain shot, but there are simple steps that can be taken to reduce the risk.

-

Arwel takes great pride in the fact that the mill has no waste whatsoever, “the peelings are used for children’s playgrounds, gardens and for farm animals in barns in the winter and the sawdust has multiple uses in gardens and farms as well.

-

Timber hauliers need to encourage young blood in, and also look after the hauliers we have, we need make the sector a safe and positive place to work.

FIND US ON

Related Posts

Forest Machine Magazine is written and edited by a forest professional with over 40 years hands on experience. We are dedicated to keeping you informed with all the latest news, views and reviews from our industry.

To support us you can subscribe to our bi-monthly magazine which is delivered to your door from only £30 per year.

Subscribe here

#homeoflogging #writtenbyloggersforloggers #loggingallovertheworld

-

1 Year Subscription£0.00

1 Year Subscription£0.00 -

2 Year Subscription£0.00

2 Year Subscription£0.00 -

Issue 38£6.00

Issue 38£6.00 -

Sustainable Logging: Powering The Planet T-Shirt£17.50 – £20.00

Sustainable Logging: Powering The Planet T-Shirt£17.50 – £20.00 -

Sustainable Logging: Powering The Planet Hoodie£33.00 – £36.00

Sustainable Logging: Powering The Planet Hoodie£33.00 – £36.00