Stumped in the Scottish Highlands With Kingwell Holdings Limited

We need more trees!

In March 2023, less than half the UK’s annual tree planting target was met. Just 12,960 ha of new woodlands were created from the 30,000-ha target. The Government has zero chance of meeting its future tree planting targets thus putting net zero ambitions at risk.

The UK currently imports 81% of the timber we require at a cost of more than £11 billion – makes you wonder why we constantly have such large roadside stocks on harvesting sites, but that’s an argument for another day. Timber insecurity is bad for the

UK’s economy and environment and it’s a proven fact trees have a positive impact on climate change. The figures prove that we require more home-grown commercial forests to alleviate our imports so why are we not hitting our targets?

In the 50’s, 60’s and 70’s, the Forestry Commission had a massive planting program which supplies the timber we harvest today. We appear though to have gone backwards since hitting this tree planting peak and it makes you wonder why the Government decided this wasn’t important. Creating new forests and woodlands are essential, but re-stocking sites which have been clear felled are equally as important for our timber reserves.

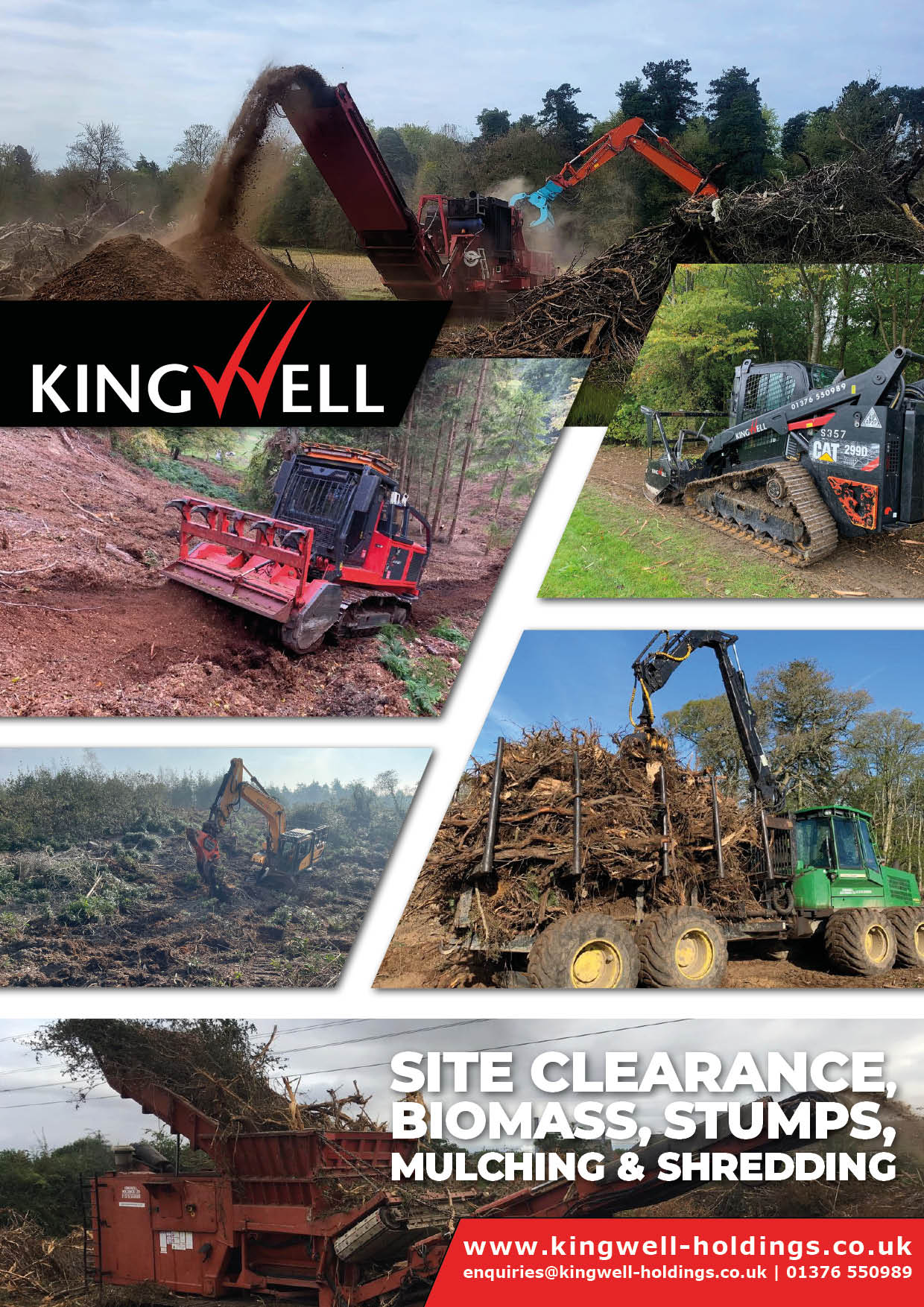

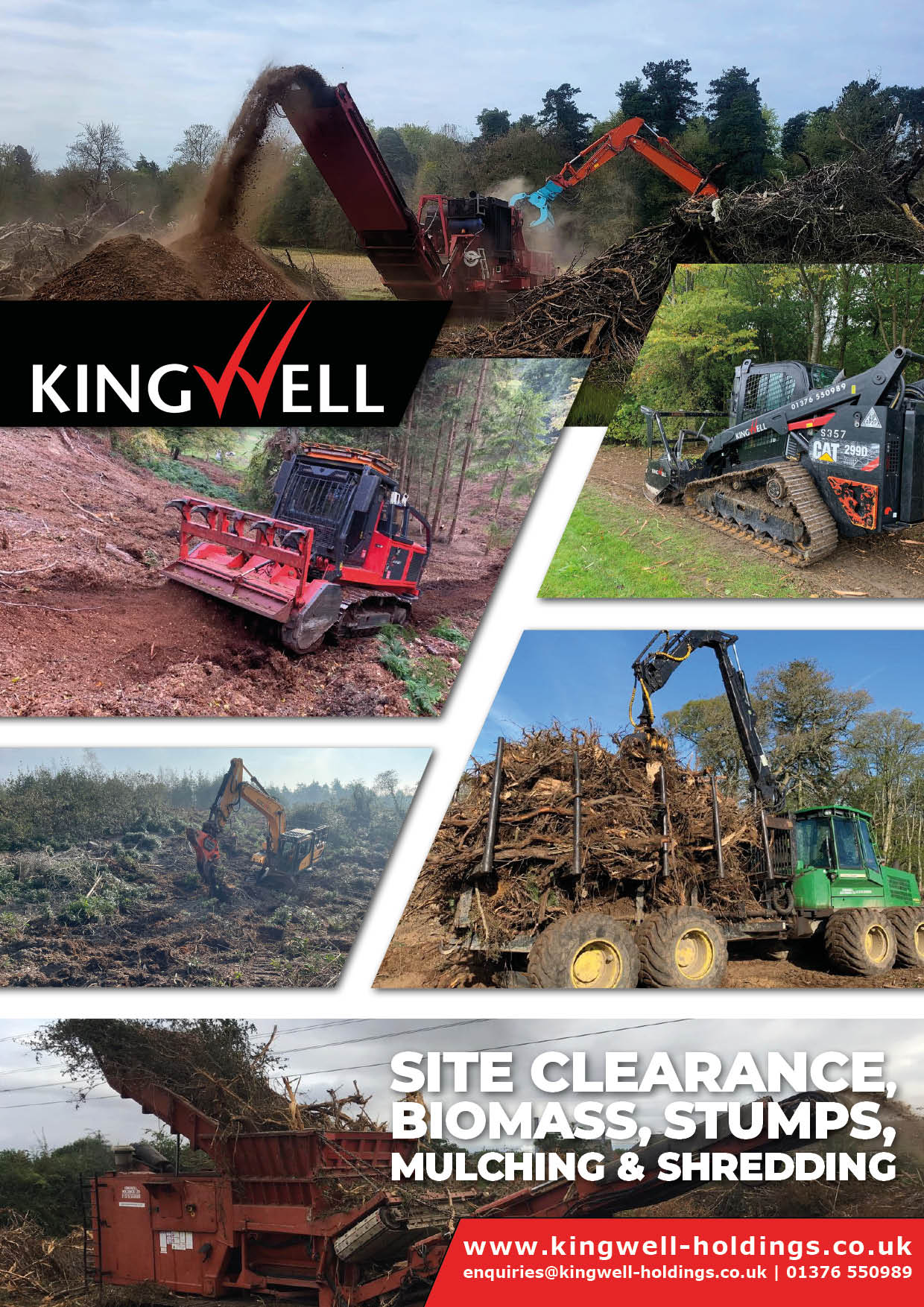

Successful replanting of a clearfelled site begins at the ground preparation stage. Kingwell Holdings, a specialist ground care company, have vast experience in preparing ground for replanting. The Essex-based company have developed a range of machinery and techniques to handle every type of de-stumping project.

Kingwell Holdings bought the assets from RGL Plant (Moffat) Ltd. in 2018, which now operate under RGL Forestry Ltd., but Bob and Justin remain very good friends and RGL Forestry continues to operate with close cooperation of Bob Little who founded the original company in the early 1970’s. All the current machinery on the RGL Forestry fleet has been designed and built by Bob and his team at the Burnfoot Yard in Moffat and the transformation of the original “Bogmaster” mulcher into the stump auger was also carried out there. Bob and his team are old-school engineers who understand exactly the rigorous demands that are required of the equipment they design and manufacture. They have a “never be beat” mentality where they can implement practical solutions for any challenges that may occur.

-

That’s a remarkable amount of work hours for a single machine, the Norcar 600 owned by Erkki Rinne is taken well care of, it even has the original Diesel engine.

-

Kieran Anders is a forestry contractor working in the lake district. His work involves hand cutting and extracting timber using a skidder and tractor-trailer forwarder.

-

It is not possible to eliminate chain shot, but there are simple steps that can be taken to reduce the risk.

-

Arwel takes great pride in the fact that the mill has no waste whatsoever, “the peelings are used for children’s playgrounds, gardens and for farm animals in barns in the winter and the sawdust has multiple uses in gardens and farms as well.

-

Timber hauliers need to encourage young blood in, and also look after the hauliers we have, we need make the sector a safe and positive place to work.

FIND US ON

Related Posts

We were invited to see the latest Stump Grinder first hand as it was working at Rosal forest in central Sutherland.

Rosal was once a thriving community of crofters who raised crops, animals and children. They were subjected to the Highland Clearances from 1750 to 1860 once the landowners realised that they could make money by offering the land for grazing sheep. Some were voluntary, but the majority by force and included burning their cottages so they couldn’t return. Many of the Highlanders left to start a new life in Canada, America, Australia, and New Zealand. Some settled on their own farms or found work on sheep farms or cattle ranches. Some lived as hunters or worked in the timber trade. Others worked in construction, built railways, tried gold mining, or started their own businesses. Many people today, living in countries like Canada and America, have Scottish ancestors who were crofters. There are still remnants of over seventy ruined buildings on the hillside overlooking Ben Loyal.

Sutherland is a beautiful part of the country to visit with spectacular scenery around every bend in the road. The roads are quiet and in good condition, sheep and red deer wander along the single-track road are undisturbed by vehicles, I know now why it takes so long to get to your destination.

The weather couldn’t have been any better when we arrived at Rosal forest, there had been an early frost which had cleared to leave a beautiful sunny winters day.

Justin Kingwell had travelled up to meet us with his operations manager, Samantha Thompson, and we were joined on site by estate forester Phil Di-Duca and machine operator Michael Quirie. Justin started out in ground care over four decades ago and is an enterprising innovator who is continually looking to progress. He has a vast knowledge in ground preparation and is always looking at ways to increase the success rate of establishing young trees in restock sites without using chemicals.

Conifer trees are at risk to pine weevils. The large Hylobius abietis is the scourge of foresters and has a preference for feeding on the bark of young trees. Conifers such as Scots pine, Sitka spruce, Douglas Fir and Western hemlock are susceptible, as weevils feeding girdles the stems. The remaining stumps on harvested sites are the idyllic habitat for weevils and a large weevil population can kill thousands of young trees on newly restocked sites. Justin decided to adopt a similar procedure as they did years ago with the Highland clearances where if you remove the weevils’ homes they will go away.

Designing and manufacturing the correct machinery for the job was not an easy task, many factors were taken into consideration. The stump grinder would primarily work on clear fells, and some of the remaining stumps were the remnants of mature trees with a large surface area. These would need a powerful motor to drive the grinding auger. Another concern was ground conditions, Sitka spruce thrives on wet boggy ground, when you consider a Sitka requires on average one gallon of water for every inch of trunk diameter, it is not surprising that the ground becomes wetter from the time of felling to replanting.

This machine is unrecognisable, it started life as a Daewoo Excavator, but almost every component within it has been transformed so it is now a 27-ton bespoke tracked platform with over 400hp and a ground pressure of just 3psi, even with the 1.1m pads that it was sat on at Rosal. It was initially built to work as a 400hp mulcher with an RGL-manufactured mulching head, capable of removing trees in extremely quick cycle times and, I have yet to see any footage of an excavator-based mulcher working faster. During the wind energy boom of the last two decades, it cleared huge areas of commercial plantations, as well as numerous peat or wetland restoration sites and worked as part of a three-machine unit that for many years, was one of the best kept mulching secrets in Scotland. Bob, his son Graeme, their engineer Wul and the RGL operators, were at the very forefront of mulching technology and dealt with some of the most challenging clearances in the North.

With large-scale mulching on wind-energy sites largely replaced with fibre extraction and with SEPA concerns over leachate from mulching operations, it was time to wind down the mulching and in 2018, the company entered the next phase of its history when it was purchased by Justin. So, in 2019 after it had completed the last mulching contract, it was decided that it would make an ideal base machine for carrying the auger and begin removing stumps.

On my arrival the Daewoo was at the roadside. After meeting everyone, Justin took the opportunity to take me around the machine to show and explain the changes that had been made. One important fact he likes pointed out is that every modification that has been carried out was done with safety in mind, as lone-working and ease of maintenance were primary objectives in the new design.

The auger drive provides vast amounts of torque to the cutting head and the entire front end from hitch to main boom base has been heavily strengthened and modified to take the extreme forces exerted on the machine from the auger. Despite this, there are still some further strengthening works planned as the forces involved can clearly be seen as the boom and dipper deform during the cutting operation. I think that a standard excavator would not last long with this attachment mounted on it. With the Rosal terrain making up a mixture of steep slopes, wet holes, and deep peat, all sprinkled with granite bounders and solid outcrops below the surface, a durable track base was another key design requirement and in current form, the machine operates at a very respectable footprint of just 3psi, for extremely wet areas this can be further reduced with wider tracks, if required. The standard undercarriage did not survive the first six months of operation and in a recent update, Forest Machine Services from Northumberland fitted extra track skis, and made other modifications to reduce track wear and lessen the risk of track derailment. These are designed to keep the tracks running straight when travelling over rough ground and obstacles.

The machine is a powerhouse and utilises a Mercedes V8 engine with 420hp, so is easily capable of shredding large surface area tree stumps in both soft and hardwoods. It is currently clearing areas of all sizes and species with an average cycle time of just 40 seconds per stump.

The cab and upper body are almost unrecognisable from the original Daewoo. Next to the cabin on the front of the excavator is a full-sized door with a short walkway which gives access to all the inner workings and engine bay. Once inside I realised just how much thought had gone into the design and layout, with all the original electrics and hydraulics replaced. The hydraulics were laid out so that every hose and fitting was easily accessible, and the electrical system was at head height so that if the machine did get bogged the expensive electrical components were at the highest possible point to prevent any water damage.

Two hydraulic tanks and extra cooling have been installed so that the hydraulics run at just 60° no matter what the weather or how hard it is working. With all round access to the engine, hydraulic and drive pumps, servicing is a breeze. There is even a storage area for waterproof clothing, tools, spare parts and hoses. The fire system has been designed so that all areas are protected should a disaster occur.

Looking underneath the excavator I saw that even the chassis had been thought of, it resembled the hull of a boat and would easily slide over any obstacles when travelling.

I took the opportunity to speak to the operator, Michael Quirie. Before joining Kingwell Holdings, he had spent many years as an LGV driver and mobile chipper operator.

“I love operating the Stump Auger,” said Michael as he pointed to an area he had just completed. “Seeing the amount of ground I cover each day and the end result gives me an immense feeling of satisfaction, accomplishment and pride.”

Although the area is remote, he has his caravan nearby with mains electricity, so Michael is quite happy in his home from home. There is a ranger on site most days and the phone works in some areas of the forest. A lone working procedure is in place and a satellite phone is on hand for any emergencies – although many areas of Scotland are in a remote location, Rosal forest is just an hour and a half’s drive to Wick General Hospital for A&E services and the air ambulance is stationed at Aberdeen which is just a short flight away.

You can see how effective this machine is as soon as it is working. It works just like a big drill by planning 30mm thick shavings from the stump as it eats its way through. The boom has been significantly strengthened from tip to base as there is immense torque from this auger. It doesn’t look that fast when rotating but it is incredible how quickly it completes the task. Despite the powerful rotation there is no flying damaging debris. The auger bit itself is of a robust construction as it works on rocky ground conditions. Rocks can become embedded into tree stumps, so it was designed with this in mind and made so that it was able to withstand harsh treatment. The auger has well in excess of 100,000 stumps destroyed, with very little wear apparent. Blades are changed as ground conditions dictate.

This was the perfect site as most of tree stumps were under the 1.2m width of the auger so they were planed in one pass. It was averaging about 40 seconds per stump, steep and soft ground can slow its progress, but it will still manage half a hectare per day on challenging conditions.

I watched it working for almost two hours and was in awe of the quality of the work it was doing. There are so many positives to using this stump auger: –

- Reducing the forests establishment costs

- Removing weevil habitats without the use of chemicals.

- Adding nutrients to the soil from composting stump plannings

- Breaking up the soils hard pan which improves drainage and prevents topsoil erosion.

- Root growth improves and the trees are much healthier due to improved soil health.

- If scarifying or mounding is required, it increases productivity thus reducing costs.

Phil Di-Duca is the forester for Kelpie Woodlands and manages Rosal Forest on behalf of Mackay forestry and farming. The Mackay family are one of the old Clans from the far north of Scotland. Their prestigious roots date back to the times of Robert the Bruce, who they once supported during the wars of Scottish independence. Their territory consisted of Farr, Tongue, Durness and Eddrachillis in the northwest county of Sutherland and they had roots in the old Kingdom of Moray.

The family were delighted when they purchased Rosal Forest from the Forestry Commission seven years ago. The forest has a 10-year restructuring plan as much of the existing trees suffered from recent storm damage. A felling programme of 100ha per year keeps two harvesters in full time work and all the profits from the sale of harvested timber are re-invested. Sitka Spruce accounts for 65% of the new trees planted with a mix of Lodgepole Pine and hardwoods in wet areas making up the remainder.

Phil is a big supporter of the stump auger and as Justin has been working in Rosal forest for just under a year, he can testify to the benefits it has had on his upcoming crop.

It was well worth the long drive to see the Stump Auger working, the more you look the more you realise just how well thought out and built this machine is. It is an absolute credit to Justin, Bob Little, and all the Kingwell and RGL staff involved for the thought and engineering that has made this stump auger the reliable, effective, and productive machine it is today.

What of the future, with this machine now firmly established with Kelpie Woodlands? Justin answered that with a smile on his face. “We have the next RGL machine about to get an auger and that one isn’t going to mess about with 530hp on tap. After that, we have a 625hp Cummins engine and components in the shed, so stand by!”.

It would be good if the industry supported projects like this that bring so many benefits to the table, as no grant money or investment cash has been put into the machine concept. It has been entirely funded by Justin.

If this is of interest call Justin on 01683 248220

www.kingwell-holdings.co.uk

www.rglforestry.co.uk

Forest Machine Magazine is written and edited by a forest professional with over 40 years hands on experience. We are dedicated to keeping you informed with all the latest news, views and reviews from our industry.

To support us you can subscribe to our bi-monthly magazine which is delivered to your door from only £15 per year.

Subscribe here

#homeoflogging #writtenbyloggersforloggers #loggingallovertheworld